A good safe work procedure template isn't just another piece of paper; it's a tool that walks your team through high-risk tasks, step by step. It's designed to turn complex safety requirements into clear, simple instructions that prevent incidents on site.

Why Generic SWP Templates Fail on the Job Site

Let's be honest. How many Safe Work Procedures (SWPs) have you seen that are nothing more than tick-box exercises, collecting dust in a site folder? They become useless paperwork instead of the vital safety tools they’re meant to be. This is what happens when we rely on generic, one-size-fits-all templates downloaded from the internet.

The core problem is that these documents are completely disconnected from the reality of your job site. They might list a few obvious hazards, but they're missing the specific details your crew needs to control risks for a particular task, with your specific equipment, in your unique work environment.

The Problem with Vague Instructions

One of the biggest flaws in generic templates is hopelessly vague language. What does "use caution" or "be aware of surroundings" actually mean in practice? Not much. An effective SWP needs to give direct, unambiguous instructions that leave zero room for interpretation.

For example, instead of a useless line like "handle chemicals safely," a proper procedure would specify: "Wear nitrile gloves and safety goggles when decanting sodium hypochlorite. Work in a well-ventilated area with the extraction fan running." That level of detail is what makes safety practical.

An effective safe work procedure template is built for the task, not just for the folder. It must be specific enough that a new worker can understand the sequence, hazards, and controls without needing to guess.

Missing Critical Site-Specific Details

Every construction site, factory, or workshop has its own set of challenges. A generic template from a website can't possibly account for these crucial variables.

- Site Layout: Are there overhead power lines nearby? What about underground services or tight access points that change how a job is done?

- Equipment Variations: Is the team using a specific brand of excavator with unique controls? Or a new type of welding machine with different settings?

- Environmental Factors: Will the team be working in extreme heat, pouring rain, or high winds? These conditions dramatically affect the task and the risks involved.

When you build a purpose-built SWP template, you're forced to think through the job from start to finish, considering the real-world context of where and how it will be done. This simple shift in approach transforms it from a generic checklist into a genuine plan for completing the work safely.

Ultimately, a good template is the foundation for a procedure your team will actually pick up and use, because it reflects the work they do every single day.

Laying the Foundation: Core Sections of Your SWP Template

A solid SWP template is more than just a box-ticking exercise; it's the backbone of a safe operation. A well-structured document guides a worker logically from prep to pack-down, while a confusing one gets shoved in a glovebox and ignored. The difference comes down to getting the core sections right.

First up, you need the administrative and contextual info. This isn't just bureaucratic fluff. It’s about making sure everyone on a busy site knows they’re using the latest, correct procedure for the exact job in front of them. It's a simple checkpoint that prevents a surprising number of mix-ups.

From there, the template needs to get into the details: the specific tools, equipment, and protective gear required. Being vague here is a recipe for disaster. Ambiguity is what leads to workers grabbing the wrong gear or making unsafe substitutions just to get the job started.

Getting the Administrative and Contextual Details Right

Before a worker even thinks about the first step, they need to know what they're looking at. The top section of your template should provide immediate clarity and version control. Think of it as the cover page of a manual with all the critical details right up front.

Make sure you nail these key components:

- Document Control: Every SWP needs a unique ID number, a version number (like V1.2), and the date it was last reviewed. This is your best defense against old, outdated procedures staying in circulation.

- Task Description: Be ruthlessly specific. Instead of “Welding Job,” go with “Tack Welding of Steel Support Beams on Level 2.” It leaves zero room for misinterpretation.

- Approvals: You need clear signature and date lines for the person who prepared it, the supervisor who reviewed it, and the manager who signed off on it. This simple step drives accountability.

Getting these details locked down is fundamental. In the world of safety, a procedure without a version number or a review date is an uncontrolled document, and that’s a massive blind spot you can’t afford.

Defining Operational and Safety Requirements

Once the admin is sorted, your SWP template needs to pivot to the practical side of things. This section acts as a pre-start checklist, ensuring your crew has everything they need before the real work begins.

This is where you translate your risk assessment into tangible, on-the-ground requirements for the team.

The goal here is simple: make preparation foolproof. A worker should be able to scan this section and know exactly what tools, PPE, and permits they need before they even think about starting the job.

Your operational section must include:

- Required PPE: Don’t just write “standard PPE.” Spell it out. For example: “Hard hat, steel-toed boots, high-visibility vest, cut-5 rated gloves, and safety glasses.”

- Plant and Equipment: Name the specific machinery. Not just "grinder," but "Hilti TE 70 Combihammer" or "5-tonne overhead gantry crane." Specificity matters.

- Training and Licences: List any non-negotiable competencies. This could be a "Working at Heights ticket," "Forklift Licence (LF)," or "Confined Space Entry permit."

- Emergency Procedures: This has to be task-specific. For a welding job, instead of a generic "call 000," try: "In case of fire, use the dry chemical extinguisher located at Grid C4. For burns, the first aid station is at the site office." That's genuinely helpful information.

By detailing these elements so clearly, you’re creating a template that actively helps workers prepare properly. And as any experienced supervisor knows, good preparation is half the battle in getting a high-risk job done safely.

To bring it all together, here’s a simple table breaking down what these essential sections look like in practice.

Essential Sections for Your SWP Template

This table gives you a snapshot of the mandatory sections that form the foundation of any effective Safe Work Procedure, especially in high-risk industries like construction and manufacturing.

| Section Title | Purpose | Example Content Snippet |

|---|---|---|

| Document Control | To manage versions and ensure the procedure is current. | SWP No: CON-045 | Version: 1.1 | Review Date: 25/11/2025 |

| Task Description | To define the exact scope and nature of the work. | Installation of prefabricated concrete wall panels via mobile crane. |

| Required PPE | To list the specific personal protective equipment needed. | Hard hat, safety glasses, steel-toed boots, rigger's gloves. |

| Emergency Steps | To provide immediate, task-specific instructions for what to do if things go wrong. | In case of uncontrolled lift, clear the 20m exclusion zone immediately. |

Having these sections clearly defined in your master template ensures consistency and makes sure the critical information is always front and centre, right where your team needs it.

How to Write Procedure Steps People Will Follow

The heart of any good SWP is the procedure itself. If the steps are vague, confusing, or just don't match what happens on the ground, the whole document is a waste of time. This is where we get practical: turning theory into clear, step-by-step instructions that will actually keep a worker safe.

Let's be clear: writing good procedure steps isn't about being a literary genius. It's about being a clear communicator. The whole point is to break a complex job down into a simple, logical sequence that anyone with the right training can follow without a second thought. Ditch the jargon and corporate speak. Keep it direct and simple.

Break Down the Task Before You Write

The first thing to do when writing a procedure is to stop writing. Seriously. Before you type a single word, you need to analyse the task from start to finish.

The best way to do this? Go talk to the people who do the job every single day. They know the unofficial shortcuts people take, the common frustrations, and the real-world hazards a manager sitting in an office might never see.

This process is a lot like putting together a Job Safety Analysis, where every single action is pulled apart to find the risks. If you need a refresher on how that works, have a look at these helpful job safety analysis examples to see how different tasks are deconstructed.

Once you have a full picture of the job, list every action in order. Don't stress about getting the wording perfect just yet. Just focus on getting the flow right, from the initial setup right through to the final clean-up.

Connect Each Step to Hazards and Controls

This is where the real work happens. For every single step you've listed, you have to clearly link the action to its specific hazards and the controls needed to manage them. Vague warnings like "be careful" are completely useless. Actionable instructions are what prevent incidents.

Let's take a common workshop task: cutting steel with a portable angle grinder.

- Vague Step: "Cut the steel beam carefully."

- Actionable Step: "Step 4: Grind steel channel to length. Hazard: Flying sparks and hot metal fragments. Control: Wear AS/NZS 1337.1 certified face shield and fire-retardant overalls. Keep a 5-metre exclusion zone marked with cones."

See the difference? The second example is powerful because it’s specific. It tells the worker exactly what to do, what the real danger is, and precisely how to stay safe. There's no room for guessing.

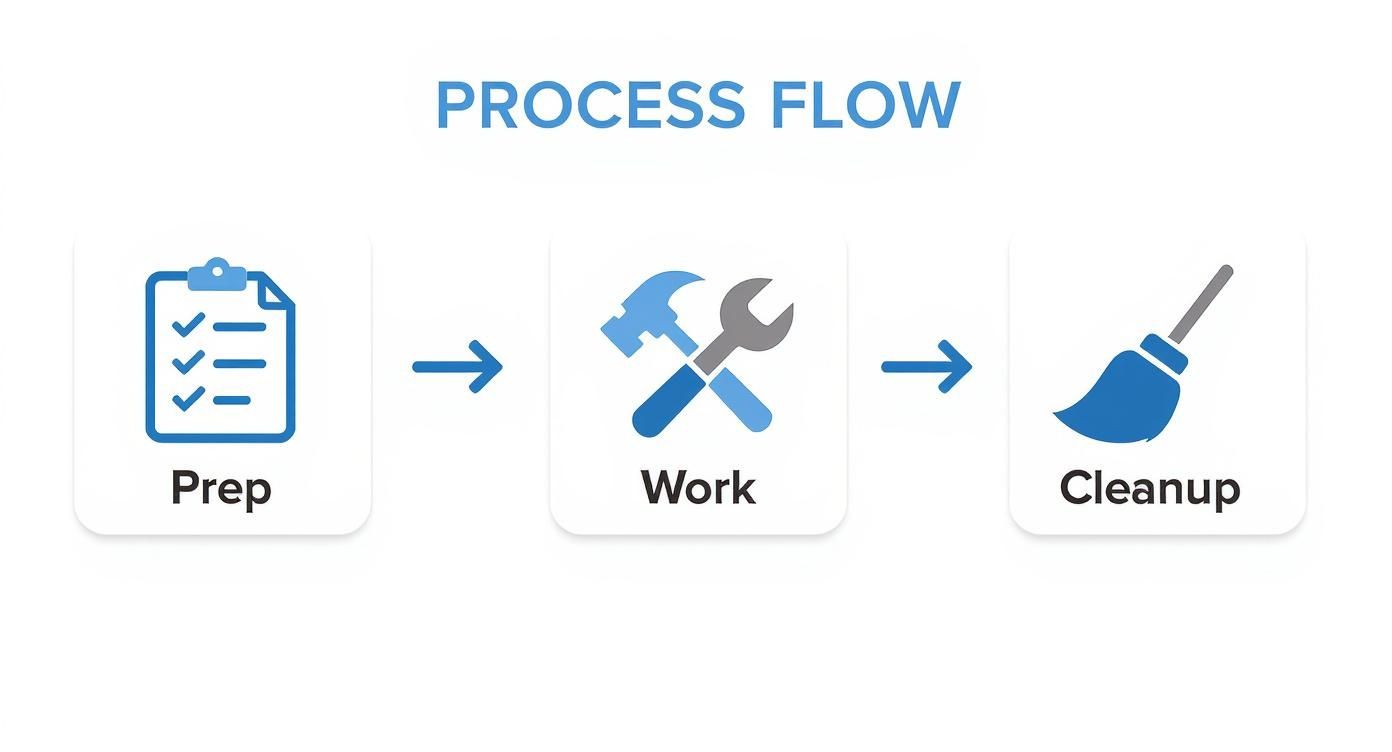

This simple flow is what every procedure should follow.

This Prep-Work-Cleanup model makes sure your procedure covers the entire job, leaving no dangerous gaps in the process.

Use Direct and Simple Language

Your workforce is diverse. You’ll have seasoned veterans working alongside brand-new apprentices, and for some, English might not be their first language. Your procedures must be written so the least experienced person on the crew can understand them without having to ask for help.

Here’s how to get that clarity:

- Use Active Voice: Start sentences with a verb. "Check the pressure gauge" is much clearer than "The pressure gauge should be checked."

- Keep Sentences Short: Stick to one action per sentence. Long, complicated sentences are a nightmare to follow on a noisy site.

- Define Acronyms: The first time you use an acronym like LOTO (Lockout/Tagout), write it out in full. Don't assume everyone knows what it means.

The latest work health and safety statistics from Safe Work Australia show exactly why this matters. There were 146,700 serious claims lodged in 2023–24. Body stressing and falls, often linked to poor manual handling or unsafe procedures, made up more than half of these. Clear instructions save people from becoming a statistic.

Embed Safety Checks into the Workflow

A great SWP doesn't just list safety rules at the beginning. It builds them directly into the workflow as non-negotiable steps. This makes safety a core part of getting the job done, not some separate task you can skip.

For example, when writing a procedure for maintaining a conveyor belt, don't just put "Isolate machinery" in the PPE section. Make it a mandatory, numbered step.

Example of Embedded Safety Checks:

- Notify the shift supervisor of the planned maintenance.

- Proceed to the main control panel for the conveyor line.

- Step 3: Isolate Energy Source. Switch the main isolator to the 'OFF' position.

- Step 4: Apply Personal Danger Tag and Lock. Attach your personal lock and tag to the isolator switch.

- Step 5: Test for Zero Energy. Attempt to start the conveyor from the local control station to confirm it is de-energised.

- Only once zero energy is confirmed, proceed with maintenance.

By embedding checks like this, you create a process that forces a worker to stop and verify that a critical safety control is in place before they can move on. This structured approach is far more effective than a simple warning. It turns the SWP from just another piece of paper into a practical tool that actively guides people to work safely.

Meeting Australian WHS Compliance Requirements

Creating a solid safe work procedure isn't just a box-ticking exercise for your operations; it’s a non-negotiable legal requirement in Australia. Staying on the right side of Work Health and Safety (WHS) laws means baking specific legal duties directly into your procedures. This isn't about adding another layer of paperwork. It's about making sure your processes genuinely protect your team and meet your obligations.

The entire WHS Act is built on one core principle: consultation. This means you have a legal duty to talk to your workers and their Health and Safety Representatives (HSRs) when you develop and review procedures, especially for anything high-risk. Skipping this step doesn’t just get you a less effective SWP; it puts you squarely on the wrong side of the law.

The Duty to Consult Your Workers

Worker consultation is where the rubber meets the road. Your team on the ground has invaluable, first-hand knowledge of the real-world hazards and the practicalities of getting the job done. Bringing them into the process from the start makes the final document more accurate, more relevant, and far more likely to actually be used.

Under the model WHS laws, this consultation must cover:

- Identifying the hazards and assessing the risks tied to the task.

- Making decisions on which control measures to put in place.

- Discussing any proposed changes that could affect your team's health and safety.

By building a formal consultation step into your template's review process, you create a documented record that this crucial legal requirement has been met. From a due diligence perspective, that’s absolutely vital.

Documenting Risks and Keeping Records

Your SWP is a cornerstone of your risk management documentation. If a regulator ever shows up, they'll expect to see a clear, recorded process for how you identify hazards, assess their risks, and implement effective controls. A well-designed template gives you the perfect structure for this.

Your template absolutely must include sections for documenting the risk assessment. This demonstrates that you’ve systematically thought through the dangers and haven't just pulled controls out of thin air. Beyond that, keeping good records is non-negotiable. This means signed copies of completed SWPs, training records proving workers have been instructed on the procedure, and a log of when each SWP was reviewed and updated. These records are your proof of compliance.

Keeping clear, accessible records isn't just for compliance; it's a practical necessity. If an incident happens, these are the first documents that will be scrutinised to determine if you took all reasonably practicable steps to ensure safety.

These records are also a key part of the information you would examine during safety audits. You can find more details on how digital systems support this by exploring resources on audits and compliance.

Adapting to State-Specific Codes of Practice

While the model WHS laws provide a national framework, each state and territory can have its own specific Codes of Practice. These codes offer practical guidance on how to meet the standards set out in the WHS Act and Regulations, especially for high-risk work like demolition, asbestos removal, or crane operations.

For example, a Code of Practice for construction work might have specific line items that must be included in a Safe Work Method Statement (SWMS). Your SWP template needs to be flexible enough to accommodate these state-specific details. This could be as simple as adding a section that directly references the relevant code, ensuring your procedures are aligned not just with the Act, but with local regulatory expectations too.

The importance of tailoring procedures to high-risk work can't be overstated. In 2024, Australia recorded 188 worker deaths from workplace injuries. Vehicle incidents were the top cause, making up 42% of fatalities, while industries like transport, agriculture, and construction accounted for a staggering 72% of all worker deaths. You can learn more about these critical Australian work health and safety statistics to understand the real-world risks. This data shows exactly why a generic, non-compliant SWP template is a dangerous liability.

Using Digital Tools to Manage Your SWPs

Let's be honest. Paper-based safe work procedures stuffed in a filing cabinet are a massive liability. They’re hard to access, almost impossible to update effectively, and create major compliance headaches when you can't prove who has seen what.

Moving your SWP templates to a digital system is one of the most practical steps you can take to make your safety management actually work in the real world.

The real win here isn’t just about saving paper. It's about ensuring the worker on the tools has the current, correct procedure in their hands right now, not an old copy they found in the back of the ute. Digital tools close that dangerous gap between the office and the job site instantly.

Why Digital SWPs Are a Game Changer

The moment a paper SWP is printed, it starts to go stale. A small change in a process, a new piece of gear, or a lesson learned from a near-miss can make it obsolete overnight.

With a digital system, you can push updates out to every single team member’s device immediately. This guarantees consistency across the board and eliminates the very real risk of someone working off an old, unsafe version. It also creates a clean, time-stamped audit trail, which is your best friend when it comes to demonstrating due diligence.

Key Features to Look for in Safety Software

When you're looking at different platforms, it's easy to get distracted by flashy features you’ll never actually use. My advice? Focus on the practical functions that solve the problems you're facing every day. A good system should make managing your procedures simpler, not more complicated.

Here are the non-negotiables:

- Centralised Document Hub: You need a single source of truth where all your SWP templates and completed procedures are stored and organised. No more hunting through different server folders or Dropbox accounts.

- Version Control: The software absolutely must track different versions automatically. You need to see exactly who changed what and when, and be able to roll back to a previous version if you have to.

- Digital Sign-Offs: Workers need to be able to review a procedure on a tablet or phone and sign off with a digital signature. This captures a time-stamped record of their acknowledgement on the spot.

- Real-Time Distribution: As soon as you approve a new version of a safe work procedure template, the system should notify the relevant workers and make the updated document immediately available.

The goal is to make the right information ridiculously easy to access. If a worker has to jump through hoops to find a procedure, they just won't use it. A good digital system puts critical safety information directly into their hands, right when they need it.

Connecting SWPs to the Bigger Picture

The real power of going digital comes from connecting your SWPs to other parts of your safety system. This is where tools like Safety Space's health and safety compliance software really start to shine. Instead of having a bunch of isolated documents, you create an interconnected system that actually manages risk.

For example, you can link a specific SWP directly to:

- Training Records: Ensure only workers with the correct, verified training can access and sign off on a procedure for a high-risk task.

- Site Inductions: Make reviewing and acknowledging key SWPs a mandatory step in a worker's site induction process before they even set foot on site.

- Plant and Equipment Registers: Link the procedure for a specific machine directly to its maintenance records and pre-start checklists.

This approach creates a robust web of checks and balances that is nearly impossible to replicate with a paper-based system. And for businesses looking to develop bespoke solutions in-house, the versatile Microsoft Power Platform offers the tools to create custom SWP management applications from the ground up.

Managing Safety Across Multiple Job Sites

Keeping safety consistent across different locations is a massive challenge, especially in Australia where vast distances can create huge operational hurdles. It's a fact that workers in remote regions suffer 56% more serious injury claims. You can see how risk clusters by region and industry.

Digital tools are the only practical way to overcome this. A centralised platform allows a safety manager in a head office to instantly deploy an updated procedure to a remote construction site or a regional manufacturing plant. This ensures every single worker is operating under the same set of rules, no matter where they are.

Got Questions About Your Safe Work Procedures?

Even with the best template in the world, the real test comes when you try to apply it on a busy site. The theory is one thing, but the practice always throws up questions. Here are some straight answers to the most common queries we hear from teams on the ground in construction and manufacturing.

How Often Should a Safe Work Procedure Be Reviewed?

One of the biggest mistakes we see is treating an SWP as a "set and forget" document. For it to be worth more than the paper it's printed on, you need a solid review cycle. As a baseline, you should be reviewing every procedure at least once every two years.

But that's just the minimum. You need to pull that SWP out for an immediate review if:

- An incident or near-miss happens. This is non-negotiable. If something goes wrong, the procedure either failed or had a gap. You need to find out why and fix it, fast.

- The job changes. Bringing in a new piece of gear, switching up the materials, or changing how the task is done makes the old SWP instantly obsolete.

- A new hazard pops up. A site inspection or a sharp-eyed worker might spot a risk that wasn't on the radar before. That needs to go into the procedure.

Regular reviews aren't about ticking a compliance box. They're about making sure the document is still relevant and actually keeps your team safe from real-world harm.

What Is the Difference Between a SWP and a JSA or SWMS?

It’s incredibly common to get these terms mixed up, but they each have a distinct and important job. Confusing them can lead to some serious compliance headaches, especially when you’re dealing with high-risk construction work.

Here’s how to think about it in simple terms:

- A Job Safety Analysis (JSA) is the thinking before the work starts. It’s the process of breaking down a job, spotting all the things that could go wrong (the hazards), and figuring out how to stop them. It’s the analysis, not the instruction manual.

- A Safe Work Procedure (SWP) is the detailed, step-by-step guide on how to actually do the job safely. It’s the practical output of the JSA, turning risk controls into a clear, sequential set of actions for workers.

- A Safe Work Method Statement (SWMS) is a specific legal document you must have under Australian WHS law for any "high-risk construction work." While it covers how the job is done, its primary purpose is to outline how those high-level risks will be controlled for a specific project. Think of it as a compliance document for regulators, whereas an SWP is an operational guide for your crew.

You’d use a JSA to figure out the risks, write a detailed SWP to explain how to do the job safely, and if it qualifies as high-risk construction, you'll also prepare a SWMS to meet your legal obligations.

Who Should Be Involved in Writing a Safe Work Procedure?

The fastest way to write a useless SWP is to have a safety manager draft it alone in an office. A procedure written without any input from the people who actually do the work is almost guaranteed to fail. It will be full of gaps and miss the practical realities of the job that only experienced workers know.

To create a document that people will actually use and trust, you have to get the right people in the room.

Your SWP development team should always include:

- Experienced Workers: The people on the tools, day in and day out. They know the shortcuts people take, the real-world frustrations, and the hazards that aren't in any textbook.

- A Supervisor or Team Leader: They get the bigger picture, the workflow, the resources, and how this one task fits in with everything else happening on site.

- A Safety Advisor: This is the person who brings the formal knowledge of WHS laws, risk assessment frameworks, and technical safety standards to the table, ensuring everything is compliant.

When you build a procedure this way, it’s not just technically sound; it's practical and workable. Even better, when the team that has to follow the document helps write it, they own it. It becomes a tool they genuinely rely on to stay safe.

Ready to stop wrestling with outdated documents and build a safety system that works? The team at Safety Space can help you create a fully customised, digital platform to manage your SWPs, simplify compliance, and protect your people. Book a free demo and consultation to see how it works.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you implement the strategies discussed in this article.

Explore Safety Space FeaturesRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.