The transport chain of responsibility is a legal concept that shares accountability across the heavy vehicle supply chain. It’s no longer just the driver who is responsible. Now, anyone whose actions or decisions influence what happens on the road is held accountable, from schedulers and loaders right up to company executives.

Understanding the Chain of Responsibility

Think of it like a team sport. In the past, if a critical play failed, only the person holding the ball (the driver) got the blame. But under the transport chain of responsibility, the law looks at everyone who passed them the ball, coached the play, or managed the team. Everyone shares in the final outcome.

This legal framework was designed to get to the root cause of accidents before a truck’s engine is even started. It's built on a simple truth: many unsafe situations on our roads begin with decisions made in offices and warehouses.

How It Works in Practice

Under Australia's Heavy Vehicle National Law (HVNL), the Chain of Responsibility (CoR) places a primary duty on every party to guarantee safety. In plain English, this means you must take every step that is reasonably practical to stop a safety breach from happening.

For example, the chain can easily reach:

- A warehouse manager who lets an overloaded truck leave the depot.

- A scheduler who sets a delivery timeline so tight it forces a driver to speed.

- A company director who doesn't invest in proper training for load restraint.

The law changed the safety landscape for heavy vehicle transport. By making every link in the supply chain legally responsible for safety, it tackles systemic problems like impossible schedules and poor loading practices that push drivers into making unsafe choices.

Why This Matters for Your Business

CoR is about prevention, not just punishment. It's about spotting and managing the risks tied to your business's transport activities before they turn into incidents. This lines up with the broader principles of workplace health and safety (WHS), where everyone has a duty of care. You can find more on these core obligations in our guide on what WHS is.

The core idea is simple: if you have the power to influence a transport activity, you have a legal responsibility to ensure it is done safely. This duty cannot be delegated, even if you hire contractors to do the work.

The table below breaks down who the key "parties" in the chain are and what their responsibilities might look like.

Who Is a 'Party' in the Chain of Responsibility?

| Party in the Chain | Role | Practical Responsibility Example |

|---|---|---|

| Executive/Director | Sets the company's safety policies and budget. | Making sure the business has a Safety Management System (SMS) that addresses CoR risks. |

| Scheduler | Plans journey times and delivery schedules. | Creating realistic schedules that account for speed limits, legal driving hours, and rest breaks. |

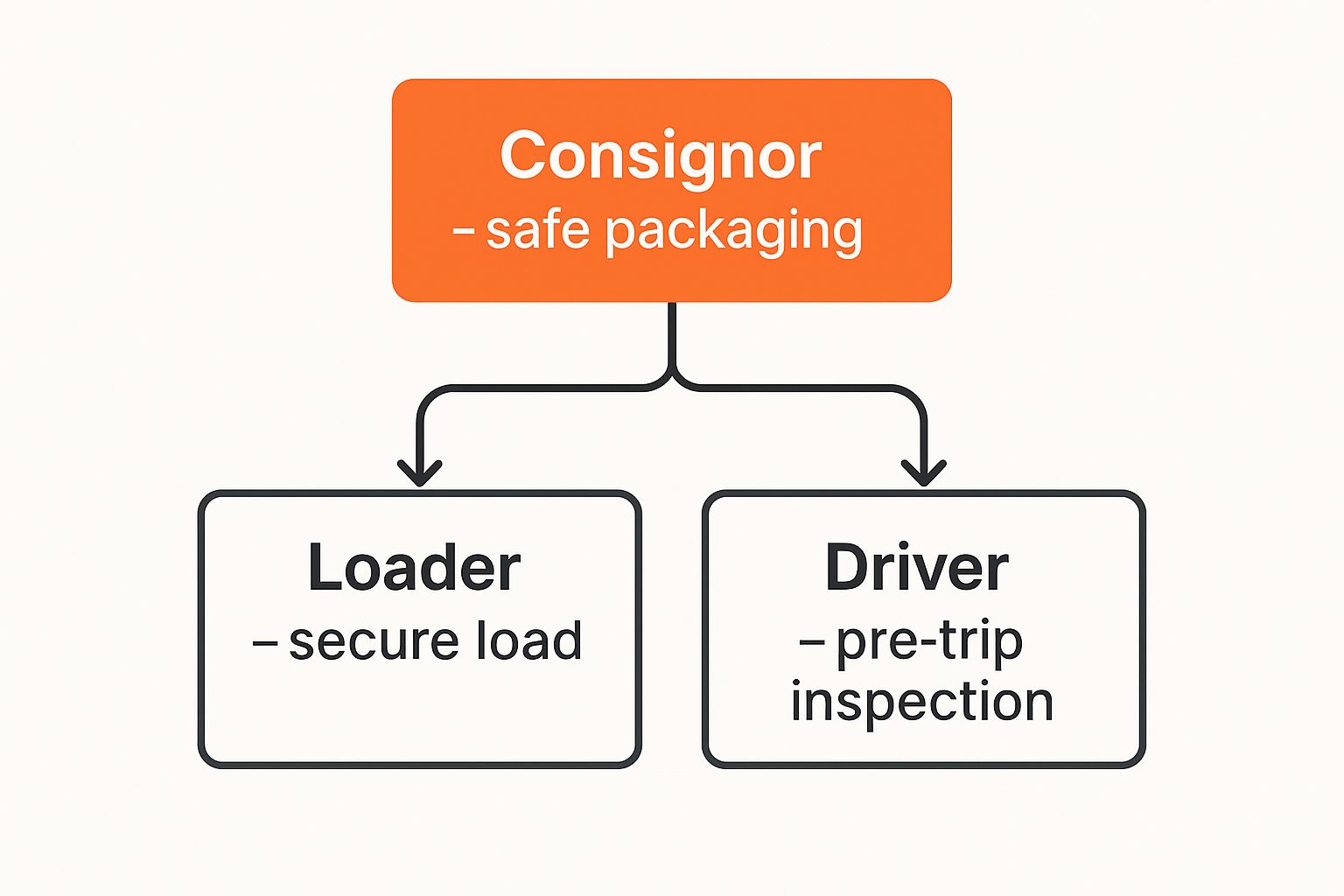

| Consignor | Sends the goods. | Accurately describing the goods, including their weight and if they are dangerous. |

| Packer | Packs goods into containers or onto pallets. | Making sure goods are packed securely so they won't shift or break loose during transit. |

| Loader/Unloader | Loads or unloads the heavy vehicle. | Securing the load correctly on the vehicle and making sure it's not overloaded. |

| Driver | Operates the heavy vehicle. | Conducting pre-start checks, obeying road rules, and managing their fatigue. |

| Operator | Manages the vehicle and driver. | Properly maintaining the vehicle and making sure drivers are fit for duty. |

Understanding where you fit in the transport chain of responsibility is non-negotiable. It’s essential for legal compliance, it protects your business, and most importantly, it saves lives on our roads by making everyone accountable for their part of the journey.

Why the Chain of Responsibility Is So Important

The transport chain of responsibility was a direct response to serious safety problems in the heavy vehicle industry. These laws exist for one simple reason: pressure from off-road parties too often creates dangerous situations on the road.

Think about it in practical terms. A scheduler sets a tight delivery deadline, and the driver is forced to choose between speeding or skipping a mandatory rest break. A loader, trying to save a few minutes, doesn't secure a pallet correctly. Miles down the road, that load shifts and causes an accident. CoR legislation connects those actions to their consequences.

The Human and Business Cost

The statistics behind these laws paint a clear picture. Between 2004 and 2014, truck crashes in Australia led to over 2,500 deaths. This data shows the serious impact heavy vehicle incidents have on road safety.

Those numbers represent a human cost, but they also translate directly into business risks. A single incident can spiral into project delays, damaged goods, ruined client relationships, and legal bills. This isn't just about ticking boxes for compliance; it's about preventing the kinds of incidents that affect families and businesses. A solid grasp of transportation risk management makes it clear why CoR is so essential.

The purpose of the transport chain of responsibility is to make safety a shared, non-negotiable part of every business decision that affects a heavy vehicle journey. It forces everyone to consider how their actions impact the driver and other road users.

Moving Beyond Just Blaming the Driver

Before CoR, the legal buck almost always stopped with the driver. If something went wrong, they were the one in the firing line. This approach failed to address the root causes of many incidents, like:

- Fatigue: Often a direct result of unrealistic schedules set by managers or clients.

- Speeding: Caused by intense pressure to meet impossible deadlines.

- Overloading: A decision made back at the depot, rarely by the driver alone.

- Poorly Secured Loads: A failure that happens during the loading process.

The law now recognizes that safety is a collective outcome. CoR provides the framework needed to hold all decision-makers accountable, creating a more effective system for managing road transport risks. It ensures safety is built into the logistics process from the start, protecting your workers, your business, and the public.

Identifying All Parties in Your Supply Chain

This diagram gives you a quick snapshot of how the chain connects just a few key roles. It’s a good visual reminder that safety isn't one person's job; it’s a shared, interconnected responsibility.

To understand your duties under the transport chain of responsibility, the first step is to figure out who is in your chain. It’s a mistake to assume it’s just the obvious roles like drivers and operators. The law includes anyone whose actions can affect the safety of a transport activity.

Think of a manufacturer sending goods to a retail warehouse. This is more than just a driver and a truck. You have a packer making sure the cartons are stable on the pallet, a loader securing that pallet inside the truck, and a scheduler setting the delivery times. Each of these people plays a part.

Mapping Your Specific Chain

The Heavy Vehicle National Law (HVNL) is specific, laying out ten functions that make up the chain. It's common for a single business to perform several of these functions at once.

- Consignor: The business sending the goods.

- Packer: The person who packs the goods for their journey.

- Loader: The individual who physically places and secures the load.

- Scheduler: The person planning the trip and delivery windows.

- Operator: The company managing the heavy vehicle.

- Driver: The person behind the wheel.

A critical point to remember is that job titles are irrelevant; it's the function you perform that matters. If a warehouse supervisor instructs a forklift operator on how to load a truck, they are legally acting as both a "loader" and a "loading manager." Just like that, they're in the chain.

The transport chain of responsibility framework isn't just for heavy freight. The Queensland Department of Transport and Main Roads makes it clear that CoR applies to others, including ride-booking companies, taxi operators, and limousine services. This wide scope shows a commitment to safety. You can learn more about these regulations on the Queensland government website.

Less Obvious But Equally Responsible Parties

Beyond the hands-on operational roles, accountability stretches right into the office and up to the boardroom. Executives and company directors are key links in this chain.

An executive who signs off on a budget that starves the fleet of proper maintenance or cuts driver training is directly influencing safety. Their decisions, made miles away from any highway, can set the stage for a serious incident.

Take a sales manager who promises a client an impossibly quick delivery time. In that moment, they are acting as a scheduler. That single promise creates a ripple effect of pressure down the entire chain, tempting a driver to speed or skip a mandatory rest break.

By mapping every single touchpoint, from the moment an order is placed to its final delivery, you can see exactly who holds responsibility. Only then can you properly manage your legal obligations and build a safe operation.

Practical Steps for CoR Compliance

Knowing you're part of the transport chain of responsibility is the first step. The real work is putting effective controls in place to manage your duties. This is about building a practical system to handle your responsibilities every day.

The aim is to build a system where safety checks are a normal part of how you do business. That means getting specific with your procedures and making them simple for everyone to follow.

Conduct a CoR Risk Assessment

You can't manage risks you don't know you have. A risk assessment is ground zero for CoR compliance. It means taking a hard look at every transport activity your business touches and asking a simple question: "What could go wrong here?"

Don't just write down "fatigue" and call it a day. Dig deeper. Is the real problem your scheduling team setting impossible deadlines? Or maybe visiting drivers have nowhere decent to rest?

A solid assessment will pinpoint:

- Specific hazards: Think overloading, speeding, poor load restraint, driver fatigue, or poor vehicle maintenance.

- Who is at risk: Your drivers, the public, your loaders, and anyone else on the road.

- Existing controls: What are you already doing to keep things in check?

- Gaps and weaknesses: Where are your current processes letting you down?

This process creates a clear map of your risks, showing you exactly where you need to focus your energy first.

Develop and Document Clear Procedures

Once you know your risks, you need to create straightforward procedures for managing them. Vague instructions won't work. Your procedures need to be specific, written down, and easy for everyone to access.

The best procedures are the ones that get used. Turn them into simple checklists, pre-start forms, or flowcharts that guide people through the right steps every single time. It takes the guesswork out of the equation.

For example, a Driver Pre-Start Checklist could include quick prompts for checking load security, tyre condition, and their own fitness for duty. For the loading team, a Load Restraint Checklist could verify that weight limits are respected and the right restraints are used for the job. And, of course, securing the correct oversize transport permits before a journey begins is a non-negotiable part of the process.

Below is a quick look at some key risk areas and what you can do about them.

Key CoR Risk Areas and Practical Control Measures

| Risk Area | Potential Breach Example | Practical Control Measure |

|---|---|---|

| Speeding | Unrealistic schedules force drivers to rush. | Implement realistic delivery schedules that account for speed limits, traffic, and rest breaks. Use GPS monitoring. |

| Fatigue | Drivers work excessive hours without adequate breaks. | Enforce a fatigue management policy. Schedule regular rest breaks and monitor work diaries or electronic logs. |

| Overloading | Consignor provides inaccurate freight weight information. | Verify consignment weights before loading. Use calibrated weighbridges and document all weight checks. |

| Load Restraint | Incorrect or insufficient restraints are used for a load. | Train loaders on national standards. Provide load-specific restraint guides and conduct regular spot-checks before dispatch. |

| Vehicle Maintenance | A prime mover has faulty brakes due to poor upkeep. | Implement a documented pre-start vehicle inspection checklist. Stick to a proactive, scheduled maintenance program. |

Putting these measures into practice is how you move from just knowing about CoR to actively complying with it.

Manage Your Contractors and Suppliers

Your responsibility doesn't stop just because you've hired a third party. Under the transport chain of responsibility, you can't outsource your legal duties. You must take real steps to ensure your contractors and suppliers are playing by the rules, too.

This is where a good contractor management system is useful. These systems help you verify that your transport partners have their own safety processes in order. A dedicated contractor management system can help you document and track these compliance checks, creating a clear paper trail.

Before you bring a new transport provider on board, ask them for:

- Proof of their Safety Management System (SMS).

- Records of their vehicle maintenance schedules.

- A copy of their fatigue management policy.

Better yet, write it into your contracts. Including specific clauses that require them to comply with all HVNL obligations legally reinforces your commitment to safety and sets clear expectations from day one. It’s a vital move to protect your business from the failures of others in your chain.

What Happens When You Get It Wrong

Failing to meet your duties under the transport chain of responsibility isn't just an administrative headache. The consequences are serious, carrying massive financial penalties and, in the worst cases, even jail time. These laws have real teeth, designed to hold every party accountable for their role in preventing incidents.

When a breach of the Heavy Vehicle National Law (HVNL) occurs, investigators don't stop with the driver. They trace the incident back through every link in the chain, digging into the decisions and actions that created the unsafe situation. The goal is to find the root cause, which often starts in an office or a warehouse.

The Legal and Financial Fallout

The penalties for a breach are based on how severe the risk was. They can be applied to both the business and to individuals within that business, including managers and company directors.

- Fines: These can be very high, reaching hundreds of thousands of dollars for a company and tens of thousands for an individual. The final figure depends on the offence, with the biggest penalties reserved for reckless behavior that puts people at risk of death or serious injury.

- Court-Ordered Supervision: A court can order your business to undergo specific training, implement a formal Safety Management System, or be subjected to regular audits. This is a direct, and often costly, intervention into how you operate.

- Imprisonment: For the most severe breaches where someone's conduct is proven to be reckless and causes a fatality, individuals can face up to five years in prison. It’s a reminder of how seriously high-level negligence is treated.

It's a common misconception that only the business pays the price. The law is clear: individuals, from a scheduling manager to a company executive, can be prosecuted personally if their actions led to a safety breach.

A Real-World Scenario

Let's look at an example. A scheduling manager is under pressure to meet a client's unrealistic delivery deadline. They know the only way to make it happen is if the driver speeds and skips their mandatory rest breaks, so they create a schedule that forces exactly that.

Predictably, an accident happens due to driver fatigue.

During the investigation, authorities uncover the impossible schedule and the emails piling pressure on the driver. In this scenario, the legal fallout could look like this:

- The driver faces charges for fatigue breaches and dangerous driving.

- The scheduling manager is prosecuted for their direct role in creating the unsafe conditions.

- The transport company is hit with massive fines for failing to have systems in place to manage fatigue.

This example shows how an action in one part of the chain triggers severe consequences for multiple people. This is why documenting and investigating near misses and incidents is so critical. A solid incident management system gives you the evidence to show you’re taking your duties seriously and helps you spot risks before they lead to a disaster.

Getting CoR into Your Daily Operations

Real compliance with the transport chain of responsibility isn't about adding another checklist to your to-do list. It's about building it into your day-to-day work so it becomes normal.

The aim is to make these duties a routine part of your existing systems, not some separate task. When you get this right, compliance stops being a chore and starts supporting a safer, more efficient operation. It's about small, practical tweaks to the way your teams already work, turning legal obligations into simple, repeatable habits.

Make Training and Inductions Count

Your new-hire inductions and staff training sessions are your first and best chance to get this right. Don’t just hand someone a policy document on their first day and expect them to remember it. Instead, build practical CoR checks directly into their role-specific training.

Think about training a new warehouse loader. Their process should automatically include:

- Load restraint checks: A simple visual guide showing them how to restrain the common freight types you handle. No guesswork involved.

- Weight verification: A non-negotiable step where they check the consignment note against the actual pallet weight before it goes on the truck.

- A clear reporting process: Simple, direct instructions on what to do if they spot a problem, whether it’s a bad pallet or paperwork that doesn't add up.

This way, from day one, they learn the safe and compliant method as the only method.

Link CoR to Performance and Meetings

If you want your team to take CoR seriously, you have to show them you take it seriously. A great way to do this is to tie it directly to performance reviews for key roles.

A logistics manager or warehouse supervisor should have CoR-related goals in their performance plan. This could be hitting targets for reducing loading errors or ensuring 100% of drivers complete their pre-start checks.

When compliance becomes part of someone’s job description and performance metrics, it gets the attention it deserves. It sends a message that these duties are just as critical as hitting delivery deadlines.

Make it a regular talking point in your operational meetings, too. A quick, standing agenda item like "CoR Risks and Incidents" keeps it front of mind. Talking about near misses or asking teams what challenges they’re facing helps you catch problems before they turn into serious breaches.

Finally, simple, physical tools are the last piece of the puzzle. A laminated pre-start checklist for drivers or a straightforward load verification form for dispatch staff makes compliance a tangible, trackable action, not just a vague idea.

Common Questions About CoR

Does CoR Really Apply to My Small Business?

Yes, absolutely. The transport chain of responsibility isn’t just for big companies. It applies to every single party in the supply chain, no matter how small your operation is.

If your business has a hand in packing goods, loading a truck, or scheduling a delivery for a heavy vehicle, you have a legal duty. Even a one-person business has to show they’re taking reasonable steps to prevent safety breaches.

What Does 'Reasonable Steps' Actually Mean?

This is a big one. Taking ‘reasonable steps’ isn’t about creating mountains of paperwork; it’s about doing everything you practically can to manage safety risks tied to your transport activities.

It means having solid safety procedures and training in place, and actively checking that they’re working. For example, a simple, reasonable step is to check that the transport company you’re hiring has a good safety record before you give them the job. It's about being proactive, not just ticking a box.

Can I Be Held Responsible for a Contractor's Mistake?

You sure can. You can’t just hire a contractor and wash your hands of the responsibility. If you bring someone on board, you still have a duty to ensure they can do the task safely and are following the rules.

This means doing your homework: verifying their compliance, checking their processes, and setting clear safety expectations in your contracts. At the end of the day, their actions can come back to you.

Keeping track of procedures, training, and contractor compliance can feel like a full-time job. Safety Space swaps out the messy paperwork and spreadsheets for a simple, all-in-one platform, helping you manage your safety obligations without the headache. Book your free demo today at https://safetyspace.co

Ready to Transform Your Safety Management?

Discover how Safety Space can help you build a safer, more compliant workplace with our comprehensive safety management platform.

Book a Free DemoRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.