A Safety Management Plan (or SMP) is your operational playbook for keeping a worksite safe. It’s a formal, documented plan that marks the shift from simply reacting to incidents to proactively preventing them. In short, an SMP gives you a structured way to identify dangers, outline controls, and detail exactly what to do when things go wrong.

Unpacking Your Safety Management Plan

Think of it like a pilot's pre-flight checklist. Before a plane ever leaves the tarmac, the crew methodically runs through a long list of checks and procedures. They don’t just "wing it"; they follow a documented plan designed to prevent failures and ensure a safe journey.

Your Safety Management Plan does the exact same thing, just for your construction site or manufacturing facility.

And it’s definitely not just another binder designed to collect dust on a shelf. An effective SMP is a living document that every single person on site understands and uses. It provides clear, actionable steps for managing health and safety, making it a critical tool for any high-risk industry in Australia.

A Practical Framework, Not Just Paperwork

At its core, a safety management plan is all about systematic prevention. It’s a structured way to think about and control risks before they can cause harm. For years, this proactive approach has been a cornerstone of Australian safety policy, pushing industries away from reactive clean-ups and towards organised prevention.

An SMP forces you to stop and ask: "What could go wrong here, and what are we going to do to stop it from happening?" This simple question is the foundation of a safer, more predictable workplace.

The goal is to move safety from an afterthought to a planned, integral part of your daily operations. This structured approach delivers real-world results. For example, when Australia implemented a national strategy to reduce road fatalities, a targeted plan helped save an estimated 3,600 lives over a decade. It’s a powerful reminder of how a documented framework can lead to significant, life-saving outcomes. You can read more about the findings on national safety strategies.

To put it simply, here’s a breakdown of what a good SMP actually does for your team on the ground.

Safety Management Plan at a Glance

This table breaks down the core purpose of an SMP into simple, actionable goals.

| Core Function | What It Means in Practice |

|---|---|

| Defines the Rules | Everyone knows who is responsible for what, from the site manager to the newest apprentice. No grey areas. |

| Identifies Dangers | The team is trained to spot potential hazards, like an unguarded machine or a frayed electrical cord, before an incident occurs. |

| Ensures Legal Compliance | It systematically addresses your legal duties under Australian Work Health and Safety (WHS) regulations. |

| Creates Consistency | Safety isn't a matter of opinion. The same clear, proven procedures are used across all teams, sites, and projects. |

Ultimately, a well-organised plan brings clarity and consistency to your safety efforts, ensuring everyone is working from the same page to keep the site safe.

Why Australian Worksites Need a Safety Plan

On any busy Australian job site, a Safety Management Plan (SMP) is far more than just another document in a folder. It’s a core business tool. For high-risk industries like construction and manufacturing, a documented safety plan isn’t a nice-to-have; it's a legal and financial necessity. It gives you a clear, structured way to tackle workplace hazards before they turn into injuries or worse.

Without a formal plan, safety becomes a bit of a guessing game. A proper SMP cuts through the uncertainty. It defines who is responsible for what, lays out clear procedures, and makes sure every single person on site knows exactly how to work safely. This is all about protecting your people and your business from serious, preventable harm.

The Legal Side of Things in Australia

Under Australia’s model Work Health and Safety (WHS) Act, every business has a primary duty of care to protect its workers. This isn't just a friendly suggestion. For certain high-risk construction projects, the regulations are crystal clear and legally require a written WHS management plan before a single boot steps on site.

Failing to meet these obligations brings heavy consequences. Regulators can hit you with on-the-spot fines, issue stop-work orders, or even prosecute company directors for serious breaches. These penalties are designed to hold businesses accountable and can run into hundreds of thousands of dollars, not to mention the reputational damage that follows a major safety incident.

A documented safety plan is also your defence. It creates a clear record showing that you’ve taken reasonable steps to identify and control risks on your worksite, something that becomes absolutely critical during any WHS investigation or legal hearing.

Beyond Compliance: The Practical Business Benefits

While staying on the right side of the law is a huge driver, the practical benefits of a solid safety plan go straight to your bottom line. A well-run SMP is one of the most effective ways to slash workplace incidents and injuries.

Fewer incidents directly translate to:

- Less Lost Time: When workers get injured, projects grind to a halt. A safer worksite means better productivity and fewer frustrating delays.

- Lower Insurance Premiums: Insurers see businesses with a systematic approach to safety as a lower risk, and they often reward that with better rates.

- Avoiding Project Shutdowns: A serious incident can trigger a full site shutdown by regulators. That means your business bleeds time and money while investigations are carried out.

A safety plan is an investment in operational stability. Every incident you prevent is a project delay avoided, an insurance claim not filed, and a worker who goes home safely at the end of the day.

This focus on proactive safety is making a real difference. While workplace safety is still a major issue in Australia, with 200 workers fatally injured in 2023, the numbers are heading in the right direction. The country's traumatic injury fatality rate has dropped by 19% since 2013, showing that formalised safety plans are helping. Even so, Australia's fatality rate is still higher than the UK's, proving there's more work to do. You can dig into more WHS statistics on the Safe Work Australia website.

Protecting Your Most Valuable Asset

At the end of the day, the most important reason for having a safety management plan is your people. A documented plan is a clear signal to your team that you genuinely care about their well-being. It creates a predictable and organised environment where everyone feels confident that the risks have been thought through and controlled.

This builds trust and ensures everyone, from the top down to the newest subcontractor, knows their role in keeping the worksite safe. When safety procedures are clear and consistently followed, safety stops being a chore and becomes part of the daily rhythm, protecting your most valuable asset and securing your business's future.

The Key Components of a Safety Management Plan

A Safety Management Plan (SMP) isn't just one single document you file away and forget about. It's more dynamic than that. Think of it as the engine of your worksite safety program, a collection of distinct, interconnected parts that have to work together to keep everything running safely. If one part fails, the whole system is compromised.

To build a plan that actually protects people on your construction site or factory floor, you first need to understand its essential components. Getting these right is the difference between a plan that just ticks a box and one that genuinely saves lives.

1. The Safety Policy

This is the bedrock of your entire plan. Your safety policy is a clear, concise statement from senior leadership that spells out the company's commitment to a safe and healthy workplace. This isn't the place for vague corporate jargon; it needs to be direct and set a non-negotiable standard.

A solid safety policy will:

- Clearly state the company’s safety goals.

- Confirm your commitment to meeting all relevant Australian WHS laws.

- Outline who is responsible for safety at every level of the business.

This policy needs to be signed by the top brass, displayed where everyone can see it, and hammered home during every worker induction. It sets the tone for everything else that follows.

2. Hazard Identification and Risk Assessment

This is the detective work of your SMP. You can't protect your team from dangers you don't even know exist. This component is all about having a systematic process to proactively hunt for things that could cause harm, and then figuring out just how serious the risk is.

For instance, on a typical construction site, you’d be looking for hazards like:

- Working at height on scaffolding.

- Operating heavy machinery like excavators and cranes.

- Exposure to silica dust when cutting concrete or bricks.

Once you’ve spotted a hazard, you assess the risk. This is often done using a risk assessment matrix, which weighs up the likelihood of something going wrong against how severe the injury could be. A fall from a two-storey scaffold is almost certain to cause a serious injury, making it a high-priority risk that demands immediate action.

3. Risk Control Measures

Okay, so you've found the risks. Now what? The next logical step is to control them. This part of the plan details the practical, on-the-ground actions you’ll take to either get rid of the hazard completely or reduce the risk to an acceptable level. Australian WHS regulations are very clear about the pecking order here, known as the hierarchy of controls.

The best control is always elimination (removing the hazard entirely), while the least effective is relying solely on Personal Protective Equipment (PPE).

Think about it: giving a worker a hard hat doesn't stop a brick from falling. It just tries to lessen the damage. A much better control is using overhead netting (engineering controls) or, even better, designing the work so no one needs to be in the drop zone in the first place (elimination).

Your SMP must document the specific controls for each high-risk activity. For a manufacturing plant, this could mean installing fixed guards on machinery, enforcing a strict lock-out/tag-out procedure for maintenance, or bringing in mechanical aids to handle heavy lifting.

4. Training and Induction

A brilliant plan is useless if your crew doesn't know it exists or understand their role in it. This component ensures that every single person who sets foot on your site, employees, contractors, and even visitors, gets the right information and instruction to work safely.

Training has to be practical and tailored to the actual tasks people are doing. The essentials include:

- Site Induction: Covering the site-specific rules, emergency procedures, and who's who in the safety team.

- Task-Specific Training: Showing someone how to safely operate a specific machine or carry out a high-risk job like welding in a confined space.

- Emergency Drills: Making sure everyone knows what to do in case of a fire, medical emergency, or chemical spill.

And you must keep records of all training. This isn't just about paperwork; it's your proof that you've given your workers the knowledge they need to stay safe.

5. Incident Reporting and Investigation

No matter how good your plan is, things can still go wrong. This part of your SMP lays out the formal process for reporting, investigating, and most importantly, learning from accidents, injuries, and even near misses. A near miss isn't a moment to feel lucky; it's a golden opportunity to prevent a serious injury next time.

The process needs to be dead simple. Workers have to know who to report an incident to and feel safe doing it without fear of blame. The investigation that follows shouldn't be a witch hunt; it needs to dig deep to find the root cause, the real "why" behind the incident, not just point fingers.

6. Monitoring and Review

Finally, an SMP is a living document, not a museum piece. The monitoring and review component builds in a process for regularly checking if the plan is actually working and making improvements where it isn't. This is what keeps your safety efforts sharp and effective over time.

You should review your plan at least once a year, or more often if:

- A serious incident or near miss occurs.

- You bring in new machinery or change a work process.

- There's an update to WHS legislation.

This constant cycle of planning, doing, checking, and acting ensures your safety plan stays relevant in an ever-changing workplace. These elements aren't just isolated checklist items; they weave together to form a powerful, cohesive structure. For a deeper dive into how these parts connect, exploring a complete safety management system can provide valuable context. To see how these fundamental elements are integrated into real-world applications, review these six top safety management system examples across various industries.

How to Build a Practical Safety Management Plan

Trying to create a Safety Management Plan (SMP) from scratch can feel like a mammoth task. But it doesn't have to be. A truly practical, effective plan isn’t about writing a perfect, thousand-page document that no one ever reads. It’s about creating a straightforward, genuinely useful tool that your team will actually use to stay safe on site.

The secret is to focus on action. The best safety plans are built with direct input from the people doing the work, tackling the real-world hazards they face every single day. Think of it as a living document that guides your daily operations, not a file that just sits on a shelf collecting dust.

Start With Clear Responsibilities

Before you type a single word, you need to be crystal clear on who is responsible for what. A plan with vague ownership is a plan that’s destined to fail from the get-go. Assign specific safety management roles to specific people on your team.

For instance, who is on the hook for:

- Conducting weekly site safety inspections?

- Delivering safety inductions to new workers and subcontractors?

- Updating the risk register when a new hazard pops up?

- Leading incident investigations?

Pinning these tasks to specific roles (like a Site Manager or WHS Officer) leaves no room for confusion. It makes it obvious who needs to act and builds accountability right into your process. Without this step, crucial safety duties can easily fall through the cracks.

Consult the People Doing the Work

Your workers on the factory floor or on the construction site are your number one source of truth when it comes to what's actually dangerous. They’re the ones who see the near misses and have to navigate the daily risks. Trying to build a plan without their input is a surefire way to miss critical hazards.

Set up simple ways to consult with them, like during toolbox talks or through a dedicated safety committee, to get their direct feedback. Ask simple questions like, "What's the most dangerous part of your job?" or "What's one thing we could do right now to make this task safer?" Their insights are gold for building a plan that actually reflects reality.

This collaborative approach is a cornerstone of Australia’s proactive stance on safety management. This focus on getting ahead of risks and involving workers pays off. To put it in perspective, New Zealand’s construction industry fatality rate is 4.41 per 100,000 workers, which is significantly higher than Australia's 2.93. It's a stark reminder of how a practical, inclusive planning process helps save lives.

Conduct a Site-Wide Risk Assessment

With your team's input locked in, the next step is a formal risk assessment. To build a genuinely practical safety management plan, it's crucial to follow a structured approach, often detailed in an operational risk management framework, which helps you systematically find, assess, and control workplace risks. This means walking through the entire worksite and identifying every potential hazard you can find.

Once you’ve listed the hazards, you need to rate the level of risk. This is usually done with a simple risk matrix that looks at two things:

- Likelihood: How likely is it that something could go wrong? (e.g., Rare, Unlikely, Possible, Likely, Almost Certain)

- Consequence: If it does go wrong, how bad would it be? (e.g., Insignificant, Minor, Moderate, Major, Catastrophic)

A risk score is calculated by multiplying these two factors. A task that is 'Likely' to cause a 'Major' injury will get a high-risk score, demanding immediate and robust controls.

This process helps you prioritise your efforts, allowing you to focus first on the hazards that pose the biggest threat to your workers. Make sure you document every single hazard, its risk score, and the control measures you'll put in place to manage it.

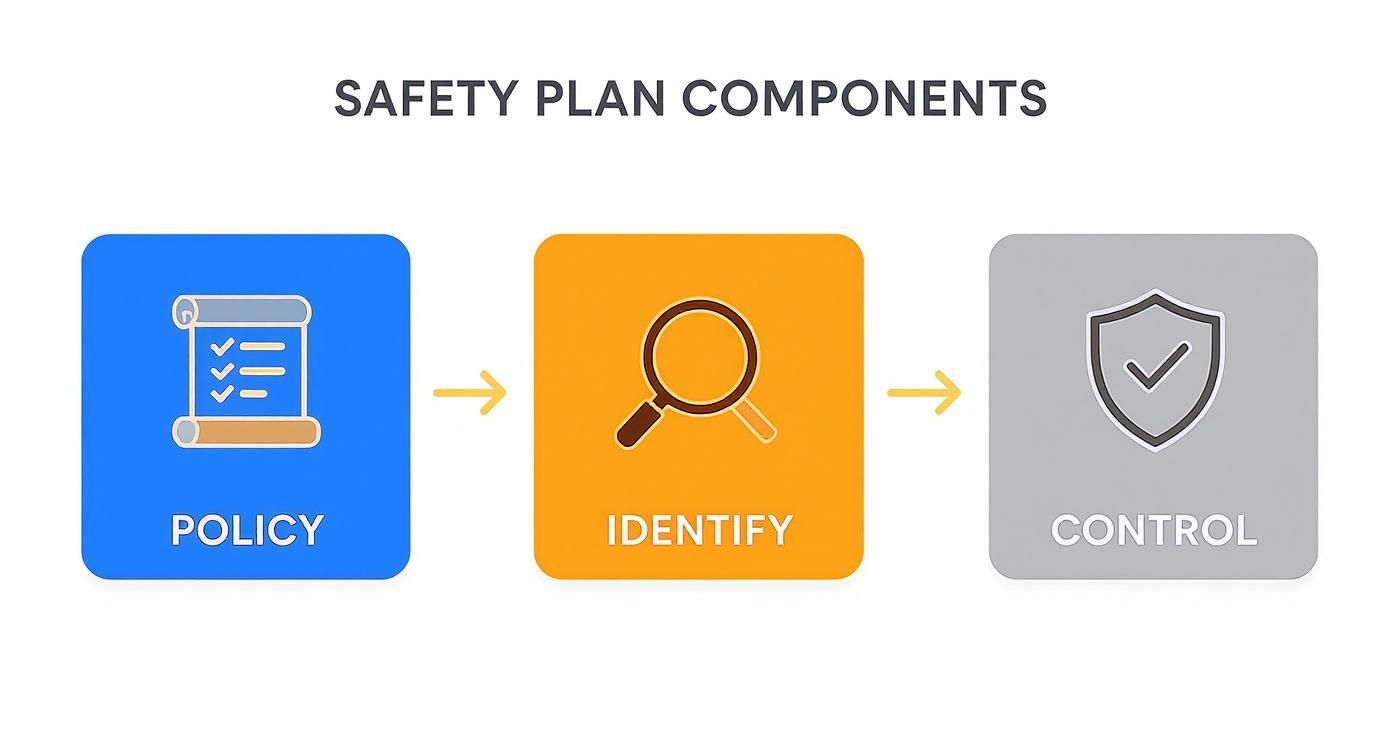

This simple diagram shows the core process flow for building out the key parts of your safety plan.

It’s a logical progression: start with your safety policy, then move to identifying risks and implementing controls.

Document and Review Your Plan

Finally, it's time to pull all this information together into a clear, easy-to-read document. A great way to start is by using a structured template. It ensures you cover all the necessary bases without having to stare at a blank page. You can find a solid foundation by checking out this https://safetyspace.co/health-and-safety-management-plan-template to guide your structure.

Your documented plan should clearly lay out your safety policy, assigned responsibilities, risk assessments, documented controls, and procedures for emergencies and incident reporting.

But the most important part? Schedule regular reviews. A safety plan should be looked at least once a year, or anytime there's a significant change on site, like bringing in new equipment or after a serious incident. This is what keeps your plan relevant, effective, and alive.

Common Mistakes That’ll Derail Your Safety Management Plan

An SMP is only worth the paper it’s written on if it’s actually used. Too often, a well-intentioned plan gathers dust on a shelf, becoming a paperwork exercise that does nothing to protect people on the ground.

Knowing the common tripwires is the first step to making sure your plan is a living tool that works in the real world. Let’s break down the four biggest mistakes we see time and time again.

Mistake 1: The Generic, "Fill-in-the-Blank" Plan

This is easily the most common mistake. Someone downloads a generic SMP template, slaps the company name on it, and calls it a day. But every worksite is unique, with its own specific layout, machinery, and high-risk tasks.

A plan designed for a high-rise construction project in Sydney simply won't cover the real-world risks of a manufacturing facility in regional Queensland. A template is a starting point, not the finish line.

How to fix it: Use that template as your skeleton. Then, get your team and do a detailed walkthrough of your actual site. Identify the hazards your workers face every single day and build the plan around managing those specific risks head-on.

Mistake 2: The "Set and Forget" Mentality

Another classic blunder is treating the SMP as a one-and-done task. Workplaces are always changing. New machinery comes in, processes are updated, and new people join the team. A plan that was perfect six months ago could have dangerous gaps today.

This "set and forget" approach completely misses the point. Your SMP should be a live guide that reflects the current reality of your operations.

How to fix it:

- Schedule a formal review of your SMP at least once a year.

- Crucially, get into the habit of reviewing and updating the plan immediately after any incident or near miss.

- Make it a rule to revisit the relevant sections whenever you bring in new equipment, materials, or work procedures.

Mistake 3: Writing It in an Ivory Tower

A safety plan written by a manager in an office, with no input from the people actually doing the work, is doomed from the start. Your frontline workers have a practical, hands-on understanding of the real risks that you just can't see from a desk.

They’re the ones who know which machine guard is awkward to use, where the floor gets slippery after wash-down, or which corner has a blind spot for the forklift. Ignoring their expertise results in a plan that looks great on paper but is totally impractical on the floor.

How to fix it: Actively involve your workers when you create and review the SMP. Run toolbox talks focused on specific risks and ask them for direct, honest feedback. Not only will you build a more realistic and effective plan, but you’ll also get far better buy-in from the team because they helped shape it.

Mistake 4: Poor (or No) Communication

You could have the best plan in the world, but it’s completely useless if your team doesn't know it exists or doesn't understand their role in it. If the SMP isn't clearly and consistently communicated, it’s just another document lost in the system.

Workers need to know exactly what to do in an emergency, how to report a hazard they’ve spotted, and what safety controls are required for the specific tasks they perform.

How to fix it: Make the SMP a core part of your site induction for every single new employee and subcontractor. Use your regular toolbox talks to reinforce key procedures. And post critical information, like emergency contacts and evacuation maps, in highly visible areas around the site. The goal is to make safety information impossible to miss.

Using Technology to Manage Your Safety Plan

Let's be honest, trying to manage a modern Safety Management Plan (SMP) with a stack of binders and a tangle of spreadsheets is a recipe for falling behind. Paper-based systems are slow, clunky, and almost guarantee bottlenecks. It’s an old-school approach in a world that demands real-time answers.

Technology offers a far smarter way to work. It turns your safety plan from a static document gathering dust on a shelf into a living part of your daily operations. The goal is to move safety management out of the back office and onto the worksite, right where the risks are. This shift doesn't just save a mountain of time on admin; it gives you a crystal-clear, immediate picture of what’s happening on the ground.

Making Your SMP Active, Not Passive

Using the right software completely changes how you interact with your safety plan. Instead of chasing down signatures and lost forms, you can automate critical processes and get the information you need, right when you need it. This transforms safety from a reactive chore into a proactive, ongoing activity.

Suddenly, key tasks become incredibly straightforward:

- Digital Risk Assessments: A supervisor can complete and update a risk assessment directly on a tablet from the site, even attaching photos of hazards on the spot.

- Easy Training Records: All your worker inductions, licenses, and training certificates live in one central, organised place. Better yet, you get automated alerts when a qualification is about to expire.

- Instant Incident Reporting: Workers can report a hazard or an incident from their phones the moment they see it, giving you immediate visibility before it escalates.

- Automated Reminders: You can set up automatic nudges for scheduled plan reviews, equipment maintenance, and safety audits so that nothing ever falls through the cracks.

Technology gives you a clear, unbroken audit trail for everything safety-related. When a regulator asks for a specific training record or risk assessment, you can pull it up in seconds instead of spending hours digging through filing cabinets.

This level of organisation is nearly impossible to achieve with paper. For businesses looking to make this leap, exploring different kinds of health and safety software is the logical next step to see how these features can be put into practice.

The Real-World Benefits of Going Digital

The single biggest advantage is gaining real-time visibility into your worksite’s safety pulse. A manager can see if daily pre-start checks have been completed across multiple sites without ever leaving their desk. This immediate access to information allows you to spot potential issues or compliance gaps before they snowball into serious problems.

At the end of the day, technology helps you spend less time managing paperwork and more time actually managing safety. By putting the right information at your team’s fingertips, you give them the tools to build a more responsive, accountable, and ultimately safer work environment.

Common Questions About Safety Plans

When you're trying to get a handle on your Safety Management Plan (SMP), a few practical questions always come up. Here are some straightforward answers to the queries we hear most often from site managers and business owners across Australia.

How Often Should I Review My Safety Management Plan?

Think of your SMP as a living document, not a "set and forget" file gathering dust on a shelf. It needs a thorough review at least once every 12 months to make sure it's still fit for purpose.

But sometimes, you can't wait that long. You’ll need to pull it out and update it much sooner if certain things happen.

An immediate review is essential after:

- A serious incident or a scary near miss.

- You bring in new machinery, different materials, or change up your work processes.

- The WHS legislation changes in a way that impacts your operations.

Doing this keeps your plan grounded in the real-world risks your team faces every day.

What Is the Difference Between an SMP and a SWMS?

This is a classic point of confusion, but it’s easy to clear up. The best way to think about it is scale.

A Safety Management Plan (SMP) is your big-picture strategy. It’s the overarching safety system for the entire site or project, covering all your policies, procedures, and responsibilities.

A Safe Work Method Statement (SWMS), on the other hand, is all about the details of a specific task. It's a legal requirement for high-risk construction work, and its job is to break down a single dangerous activity, step-by-step, to pinpoint the hazards and spell out the controls for that one job.

So, the SMP is the framework, and the SWMS is the instruction manual for a specific high-risk task that happens within that framework.

Does My Small Business Need an SMP?

While the legal mandate for a written SMP often kicks in for specific high-risk construction jobs, just about every business benefits from having a documented safety system. If your team faces any kind of physical risk, a formal plan is simply the best way to meet your duty of care.

It gives you a clear, organised way to identify hazards and protect your people. Plus, having a proper plan shows everyone, your team, insurers, and regulators, that you take safety seriously. It’s fundamental to building trust and protecting your business.

Ready to move your safety plan from a dusty binder to an active, digital system? Safety Space offers an all-in-one platform to build, monitor, and manage your safety compliance with ease. Get a free demo and consultation to see how it works.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you build a safer, more compliant workplace with our comprehensive safety management platform.

Book a Free DemoRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.