Running a safe workplace means knowing exactly what to look for. A good workplace inspection checklist is more than just a piece of paper; it’s a practical tool for spotting hazards before they cause harm. Forget vague theories and complex systems. This guide gives you a straightforward, organised list of 10 essential categories to include in your inspections, specifically for high-risk environments like construction and manufacturing.

We will break down exactly what to check, why it matters, and how to do it effectively. Each point is designed to be actionable, helping you build a workplace inspection checklist that actually works on-site. The focus is on practical steps, from identifying general health hazards to confirming correct machine guarding. While this guide covers broad workplace elements, it's also useful to look at specific guides, such as an equipment safety inspection checklist, to add more detail for heavy machinery.

This article provides the framework you need to create a thorough and functional checklist. Let's get started on building a document that keeps your team safe and your operations compliant.

1. Safety and Health Hazards

This is the foundation of any good workplace inspection checklist. It involves a systematic review of the physical environment to identify and control hazards that could cause injury, illness, or death. This checkpoint moves beyond simple tidiness to address tangible risks, from unguarded machinery and chemical spills to poor workstation design and potential biological contaminants. A thorough hazard assessment is a non-negotiable legal and moral responsibility, forming the base of a safe operational environment.

This process must be practical and tailored to your specific worksite. A manufacturing plant's inspection, for example, will focus heavily on machine guarding, lockout/tagout procedures, and noise levels. In contrast, a healthcare facility will prioritise checks for biohazard containment, sharps disposal, and slip risks in sterile corridors.

How to Implement Hazard Checks

For this part of your workplace inspection checklist, organise your assessment into specific categories to ensure nothing is missed. Use these actionable steps to build your process:

- Involve Your Team: Your workers on the ground have firsthand knowledge of the risks. Ask them directly about near misses, awkward tasks, or areas they avoid. Their input is invaluable for spotting issues that managers might not see.

- Document Everything: Use a digital form or a simple notebook, but record all findings. Take photos and add measurements (e.g., "walkway blocked, only 50cm clear passage"). This evidence is crucial for planning and verifying corrective actions.

- Create Action Plans: For each identified hazard, assign a responsible person, set a clear completion deadline, and describe the required fix. This turns your inspection from a list of problems into a concrete plan for improvement.

- Reference Official Guidance: Use resources like the model Work Health and Safety (WHS) laws and codes of practice from Safe Work Australia to guide your inspection criteria. This ensures your checklist aligns with national standards.

2. Personal Protective Equipment (PPE)

This checkpoint focuses on the last line of defence against workplace injuries. It involves verifying that the correct PPE is available, properly maintained, and actually worn by employees in hazardous areas. An inspection of PPE confirms that controls are in place where engineering or administrative solutions cannot completely remove a risk. This step is a critical part of a complete workplace inspection checklist, ensuring workers are actively protected.

The requirements for PPE vary greatly depending on the task and environment. On a construction site, this means checking for hard hats, high-visibility clothing, and steel-toed boots. In a laboratory setting, the focus shifts to verifying the use and condition of safety goggles, gloves, and lab coats. Each inspection must be specific to the tasks being performed.

How to Implement PPE Checks

To make your PPE checks effective and organised, integrate them directly into your site walkthroughs. Use these actionable steps to ensure your team is protected:

- Review Hazard Assessments: Check that your PPE provision aligns with your site’s most recent hazard assessment. If tasks have changed, the required PPE might need updating. This ensures your choices are based on actual risks.

- Inspect for Condition and Fit: Don't just check if PPE is present; check if it's usable. Look for cracks in hard hats, damage to safety glasses, or excessive wear on gloves. Confirm that items requiring a specific fit, like respirators, have been properly fit-tested for the user.

- Verify Accessibility and Storage: PPE must be stored correctly to maintain its integrity and be readily accessible to workers. Check that storage areas are clean, dry, and keep equipment from being damaged between uses.

- Confirm Training Records: Part of the inspection is ensuring workers know how to use, maintain, and identify damage to their own PPE. Cross-reference your observations with training records to identify any gaps in worker knowledge. To find out more, explore the requirements for Personal Protective Equipment on safetyspace.co.

3. Emergency Procedures and Exit Routes

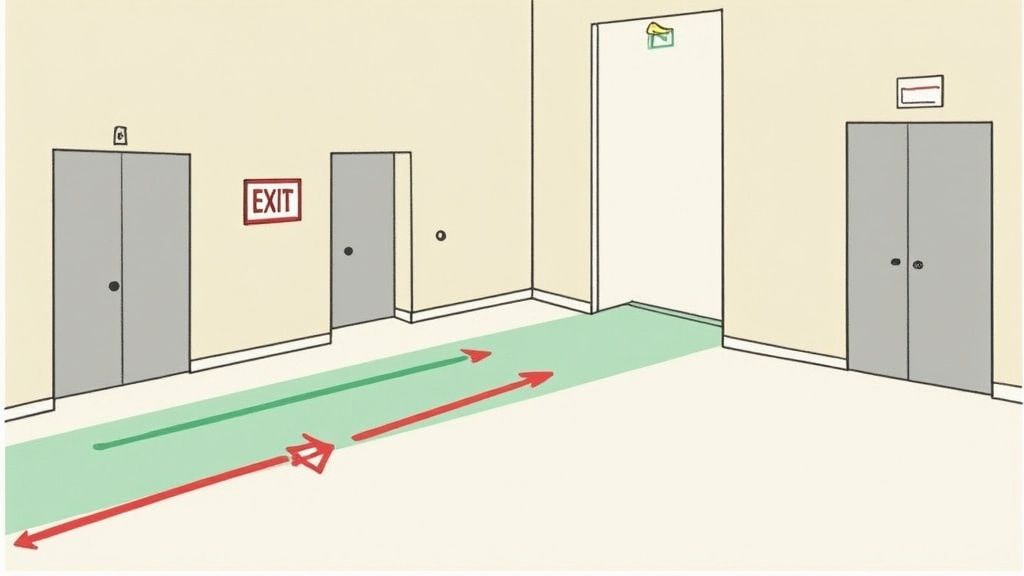

This checkpoint focuses on ensuring workers can safely and quickly evacuate the premises during an emergency. It involves a systematic evaluation of evacuation plans, the accessibility of exit routes, emergency signage, alarm systems, and employee training. A well-defined and regularly tested emergency plan is critical, as it provides a clear, life-saving script for staff to follow when faced with fire, chemical spills, or other urgent threats. Without it, confusion and panic can lead to serious injuries or fatalities.

This part of your workplace inspection checklist must be adapted to your site's specific risks. A multi-storey office building will have different needs, focusing on clearly marked stairwells and assembly points, compared to a large manufacturing facility, which might require protocols for chemical emergency response stations and lockout procedures during an evacuation. Regular fire drills and functional alarm systems are non-negotiable for any business.

How to Implement Emergency Procedure Checks

To properly assess your emergency preparedness, break down your inspection into clear, verifiable components. Use these actionable steps to build your process:

- Walk the Routes: Physically walk every primary and secondary emergency exit route. Check for obstructions, locked doors, or any materials stored in corridors that could impede a quick exit. Ensure all exit doors can be opened from the inside without keys or special knowledge.

- Verify Signage and Lighting: Confirm that all exit signs are illuminated and clearly visible from a distance. Test emergency lighting systems to ensure they function correctly during a power failure, providing adequate light for people to find their way out.

- Test Communication Systems: Activate your emergency alarms, such as fire bells or public address systems, to verify they are loud enough to be heard in all areas, including noisy production floors. Document any dead spots where the alarm is not audible.

- Review and Drill: Check that evacuation diagrams are posted and easy to understand. Conduct evacuation drills at least quarterly to familiarise staff with procedures and identify practical issues. For more detailed guidance, consider using a comprehensive emergency response plan template to cover all bases.

4. Fire Prevention and Protection

This element of a workplace inspection checklist addresses one of the most destructive potential incidents: fire. It involves a systematic check of all systems and procedures designed to prevent fires from starting and to control them if they do. This covers everything from fire detection and suppression equipment to the proper storage of flammable materials and ensuring clear evacuation routes. For high-risk industries like manufacturing or chemical storage, a solid fire safety protocol is a critical operational and legal requirement.

The specific checks will vary greatly depending on the environment. A manufacturing plant might focus on automated sprinkler systems and combustible dust control, while a commercial kitchen’s inspection will prioritise its hood suppression systems and gas line integrity. Adhering to standards set by local fire authorities and the National Fire Protection Association (NFPA) is non-negotiable for compliance and safety.

How to Implement Fire Safety Checks

To make this part of your workplace inspection checklist effective, organise your review into clear, manageable categories. Use these practical steps to build a solid process:

- Conduct Monthly Equipment Checks: Don't wait for annual inspections. Check that fire extinguishers are fully charged, accessible, and not expired every month. Ensure a minimum 1-metre clearance around all fire equipment and electrical panels.

- Verify Egress Paths: Walk all emergency exit routes. Ensure they are completely clear of obstructions, well-lit, and that all exit doors are unlocked and function correctly from the inside. This simple check can save lives.

- Review Flammable Material Storage: Confirm that all flammable and combustible liquids are stored in approved safety cabinets or designated areas away from ignition sources. Check that containers are properly labelled and sealed.

- Document and Train: Keep a detailed log of all inspections, maintenance, and fire drills. Ensure all employees are trained on basic fire extinguisher use (the PASS method: Pull, Aim, Squeeze, Sweep) and know the evacuation plan. This documentation is vital during an audit or incident investigation.

5. Electrical Safety and Equipment

This part of your workplace inspection checklist addresses one of the most serious and often hidden dangers on site: electrical hazards. It involves a systematic check of all electrical systems, from wiring and outlets to machinery grounding and lockout/tagout (LOTO) procedures. The goal is to identify and control risks like electrocution, arc flash, and electrical fires, which can have catastrophic consequences. A diligent electrical inspection is a critical legal requirement and a fundamental part of maintaining a safe working environment.

The focus of this check will vary based on your workplace. A manufacturing facility will need strict LOTO procedures for equipment maintenance and detailed inspections of high-voltage machinery. In contrast, an office building's checklist might focus more on regular testing and tagging of portable appliances, ensuring switchboards are accessible, and checking for overloaded power boards.

How to Implement Electrical Safety Checks

To make this part of your inspection effective, break it down into manageable areas. Use these actionable steps to build a solid electrical safety process:

- Establish a Clear LOTO Procedure: For any machinery that requires servicing, ensure you have a formal lockout/tagout system. This must include training for all affected workers, proper locks and tags, and a clear sequence for isolating energy sources.

- Inspect All Wiring and Components: Regularly check for exposed or frayed wires, damaged extension cords, and faulty plugs. Confirm that all electrical panels are clearly labelled, unobstructed, and easily accessible in an emergency. Never allow materials to be stored in front of them.

- Engage Qualified Professionals: All electrical installation, repair, and major inspection work must be performed by a licensed electrician. Schedule annual professional audits to assess the entire system’s integrity, especially in high-risk environments.

- Verify Equipment Grounding: Check that all necessary equipment and machinery are properly earthed to prevent electrical shock. This is a simple but critical step that is often overlooked in routine checks.

6. Machine Guarding and Equipment Safety

This critical checkpoint focuses on the physical barriers and procedures that prevent workers from coming into contact with dangerous moving parts of machinery. Effective machine guarding is a direct line of defence against severe injuries like amputations, crushing, and entanglement. The inspection must verify that guards are correctly installed, functional, and used consistently, alongside solid procedures like lockout/tagout for maintenance and servicing. This is a non-negotiable part of any workplace inspection checklist in industrial settings.

The application of this checkpoint must be specific to the equipment on your floor. For a manufacturing plant, this means checking that interlocked guards on presses stop the machine when opened. A woodworking shop’s inspection would verify that riving knives and blade guards are in place on all table saws. These measures are fundamental to preventing life-altering incidents.

How to Implement Equipment Safety Checks

To make your equipment checks effective, break them down into clear, repeatable actions. Use this process to build a reliable safety inspection for your machinery:

- Physically Check All Guards: Do not just look. Manually confirm that guards are fixed securely and cannot be easily bypassed or removed by operators. Check for damage, wear, or improper modifications.

- Test Emergency Systems: Regularly test all emergency stop buttons, light curtains, and two-hand controls to ensure they function as designed. Log the date and result of each test to maintain a clear record of equipment readiness.

- Review Lockout/Tagout (LOTO) Procedures: During the inspection, confirm that LOTO equipment is available and that workers can explain the correct procedure for isolating energy sources before maintenance. This verifies both the system and the training.

- Keep Detailed Maintenance Logs: Your inspection should include a review of maintenance records. Ensure that scheduled servicing is up-to-date and that any reported faults have been addressed and signed off.

7. Hazardous Materials Storage and Handling

This checkpoint covers the strict protocols for managing hazardous substances to prevent chemical accidents, employee exposure, and environmental harm. It involves evaluating everything from storage compliance and container labelling to the accessibility of Safety Data Sheets (SDS) and spill containment measures. Proper management of hazardous materials is a critical part of any workplace inspection checklist, mandated by regulations like the GHS and enforced by bodies such as Safe Work Australia.

The inspection process must be specific to the materials on-site. For instance, a manufacturing plant will need dedicated hazmat areas with robust spill kits, while a laboratory must focus on the correct segregation of reactive chemicals. The fundamental goal is to confirm that every hazardous substance is stored, handled, and documented correctly to minimise risk.

How to Implement Hazardous Materials Checks

To make this part of your inspection effective, focus on systematic verification and clear documentation. Use these steps to guide your process:

- Audit Your Inventory and Storage: Verify that all containers are correctly labelled according to GHS standards and are in good condition. Check that incompatible chemicals are segregated and secondary containment is in place for liquids. Part of this involves confirming that you are choosing the right chemical storage tank for your facility to meet all safety and compliance requirements.

- Check Accessibility of Safety Data Sheets (SDS): Ensure that an up-to-date SDS is readily available for every hazardous chemical on site. They must be accessible to all employees in the work area during their shift, either in a physical binder or via a digital system.

- Verify Employee Training: Confirm that all workers who handle hazardous materials have received specific training on the risks, proper handling procedures, required Personal Protective Equipment (PPE), and emergency spill response. Document all training records with dates and attendee names.

- Inspect Spill Control Measures: Locate all spill kits and check that they are fully stocked, clearly marked, and appropriate for the types of chemicals used in that area. Ensure employees know where they are and how to use them.

8. Housekeeping and Workplace Cleanliness

This checkpoint addresses the overall state of order and cleanliness in the work environment. It covers everything from clear walkways and organised storage to effective waste management and spill control protocols. Good housekeeping is fundamental to preventing common workplace incidents like slips, trips, and falls, which are among the most frequent causes of lost-time injuries. It also helps with operational efficiency by ensuring tools and materials are easy to find and access.

This part of your workplace inspection checklist must be adapted to the operational demands of your site. For example, a food processing facility will have stringent sanitisation protocols to prevent contamination, while a construction site's checklist will focus on managing debris, securing materials against wind, and maintaining clear access routes for machinery. It is a critical, ongoing process, not a one-off task.

How to Implement Housekeeping Checks

To make your housekeeping inspection effective, integrate it into daily operations and make it a shared responsibility. A clean worksite is a direct indicator of a well-managed one. Use these steps to build your process:

- Assign Specific Areas: Divide the workplace into zones and assign responsibility for the cleanliness of each area to a specific team or individual. This creates clear ownership and accountability.

- Establish Clear Standards: Don’t just say "keep it tidy." Define what "clean" means for each area. For example, "Walkways must be clear of all materials," or "All spills must be cleaned within 15 minutes using the designated spill kit."

- Use Visual Management: Mark out designated storage areas for tools, materials, and waste bins with floor tape or signs. This makes it immediately obvious when something is out of place.

- Document and Review: Take photos of both good and bad examples during your inspection. Use these visuals in team meetings to show exactly what is required and to track improvements over time.

9. Training, Competency, and Documentation

This part of your inspection confirms that your team not only has the physical tools to work safely but also the knowledge. It involves verifying that workers have received, understood, and been assessed on the necessary safety training for their roles. This checkpoint is critical because even the best equipment and procedures are ineffective if employees don't know how to use them correctly. It is a fundamental check to ensure your workforce is capable and prepared to manage workplace hazards.

A solid training program is a key part of any workplace inspection checklist. For instance, a construction site inspection would verify that all relevant workers hold current white cards and high-risk work licences. In a manufacturing plant, the focus would shift to checking records for specific machinery operator training and competency assessments. This verification process ensures that your training efforts are not just a formality but are actively helping to make the work environment safer.

How to Implement Training and Competency Checks

Organise this section of your inspection to verify both the delivery of training and its effectiveness. Use these practical steps to build your process:

- Review Training Records: During your inspection, spot-check training records for a sample of employees. Confirm that all required training is up-to-date and that records are maintained and accessible. For example, check that forklift operator licences are current.

- Observe and Ask: Watch employees perform tasks and ask them questions about the safety procedures involved. Their ability to explain the steps and identify risks is a direct indicator of training effectiveness.

- Check for Written Programs: Your organisation should have documented training programs outlining what training is required for each role, how it is delivered, and how competency is assessed. Verify this documentation exists and is being followed.

- Confirm New Hire Training: Ensure new employees and contractors receive a comprehensive safety induction before they start work. Check records to confirm this induction covers site-specific hazards, emergency procedures, and reporting processes.

10. Incident Reporting, Investigation, and Corrective Actions

This part of your workplace inspection checklist goes beyond finding hazards; it tests your system for learning from mistakes. It assesses whether your procedures for reporting incidents, investigating them to find root causes, and implementing effective fixes are actually working. A strong incident management process is crucial because it turns accidents and near misses into valuable lessons, preventing them from happening again. This system is a core component of continuous improvement and shows a commitment to operational safety and compliance.

This process is not just for major injuries. A manufacturing plant that diligently investigates near-miss reports, like a dropped load that didn't hit anyone, can fix the underlying problem before it causes a fatality. Similarly, nuclear facilities have rigorous investigation protocols for minor process deviations, ensuring small issues don't escalate. The goal is to create a reliable feedback loop where every event, big or small, triggers a structured response.

How to Implement Incident System Checks

To properly assess your incident management system, your inspection needs to verify that your documented procedures are being followed in practice. Use these actionable steps to guide your review:

- Review Documentation: Pull recent incident reports, including those for near misses. Check if investigations were started quickly, ideally within 24-48 hours, and if they identified a root cause rather than just blaming an individual.

- Verify Corrective Actions: Don't just check that a hazard was reported. Track the corrective action from the report to its completion. Is there proof the fix was implemented and is it effective? A paper trail without a real-world solution is a failure.

- Talk to Workers: Ask team members if they feel comfortable reporting incidents and near misses without fear of blame. Their answers will reveal the true health of your reporting system. A non-punitive approach is essential for getting accurate information.

- Analyse Trends: Check if incident data is being reviewed quarterly to spot recurring problems. Consistent slip-and-fall reports in one area, for example, point to a systemic issue that individual investigations might miss. For more guidance on structuring these documents, you can find a good incident reporting sample here.

10-Point Workplace Inspection Checklist Comparison

| Checkpoint | 🔄 Implementation complexity | ⚡ Resource requirements | ⭐ Expected outcomes | 📊 Ideal use cases | 💡 Key advantages / tips |

|---|---|---|---|---|---|

| Safety and Health Hazards | Medium to High | Moderate | High | All workplaces | Involve staff in ID, document findings, use OSHA guidelines |

| Personal Protective Equipment (PPE) | Low to Medium | Low to Moderate | Moderate | Construction, labs | Annual assessments, maintain inventory, provide fit-testing |

| Emergency Procedures and Exit Routes | Medium | Moderate | High | Offices, factories | Run regular drills, assign wardens, test communications |

| Fire Prevention and Protection | High | High | Very high | Chemical plants, kitchens | Inspect extinguishers monthly, keep exits clear, train staff |

| Electrical Safety and Equipment | High | High | High | Manufacturing, hospitals | Annual electrical audits, use qualified electricians, enforce LOTO |

| Machine Guarding and Equipment Safety | Medium to High | Moderate to High | High | Manufacturing, woodworking | Keep guards in place, test E-stops monthly, log maintenance |

| Hazardous Materials Storage and Handling | High | High | High | Laboratories, chemical plants | Use chemical inventory systems, SDS in local languages |

| Housekeeping and Workplace Cleanliness | Low to Medium | Low to Moderate | High | Hospitals, food service | Daily cleaning schedules, immediate spill cleanup, photo audits |

| Training, Competency, and Documentation | Medium | Moderate | High | Construction, manufacturing | Use varied training methods, test comprehension, retain records |

| Incident Reporting, Investigation, and Corrective Actions | Medium to High | Moderate | High | High-risk industries | Foster non-punitive reporting, investigate quickly, track actions |

Putting Your Checklist into Action

We've covered the ten essential areas that form the backbone of any effective workplace inspection checklist, from machine guarding and electrical safety to emergency procedures and PPE. Having this detailed list is the first step, but the real value comes from consistent application and follow-through. A checklist sitting in a folder is just a document; a checklist used actively in the field is a powerful tool for preventing incidents before they happen.

The goal isn't simply to find faults. It’s about creating a systematic process that confirms your safety controls are working as intended, day in and day out. Think of your workplace inspection checklist as a proactive communication tool. It helps you identify small issues, like a blocked fire exit or a frayed electrical cord, before they can escalate into major problems that lead to injuries or work stoppages. A consistent inspection routine builds a reliable picture of your operational risks.

From Paper to Practice

The most significant challenge is often moving from theory to execution. How do you make sure inspections are actually completed, findings are documented correctly, and corrective actions are assigned and tracked? The key is to make the process as straightforward as possible for the people doing the work.

- Customise your list: Don't use a generic template. Take the ten points covered in this article and adapt them to your specific site, whether it's a busy manufacturing plant or a multi-stage construction project. Remove what isn’t relevant and add items unique to your operations.

- Assign clear responsibility: Everyone should know who is responsible for conducting inspections, who needs to sign off on them, and who is accountable for fixing any identified hazards. This clarity prevents issues from being forgotten or ignored.

- Close the loop: Finding a problem is only half the job. A strong system must track every issue from identification through to resolution. Documenting that a hazard has been fixed is just as important as finding it in the first place.

Ultimately, a well-implemented workplace inspection checklist transforms safety from an abstract idea into a series of tangible, repeatable actions. It provides the structure needed to manage risks effectively and gives you the verifiable data to prove your safety systems are functioning. By integrating these checks into your daily operations, you are not just complying with regulations; you are actively building a more predictable and secure work environment for everyone on site. This systematic approach is fundamental to reducing workplace incidents and ensuring your projects run smoothly and safely.

Ready to make your inspection process more efficient and reliable? Safety Space allows you to build custom digital checklists, assign corrective actions instantly, and track everything in one easy-to-use platform. See how it works by visiting Safety Space and get control over your workplace safety management.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you build a safer, more compliant workplace with our comprehensive safety management platform.

Book a Free DemoRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.