When you're faced with a hazard in the workplace, your first instinct might be to find a quick fix. But the best safety pros know that not all solutions are created equal. That's where the hierarchy of controls comes in. It’s a simple but powerful framework that forces you to think smarter, not harder, about risk.

It ranks safety solutions from the most effective and permanent down to the least reliable. Think of it like this: if a pipe is leaking, you could just put a bucket under it. But isn't it better to fix the pipe itself? The hierarchy of controls pushes you to fix the pipe first.

What Is The Hierarchy of Controls?

At its core, the hierarchy of controls is a system for prioritising how you manage risk. It’s designed to guide you away from temporary fixes and toward more robust, permanent solutions that actually remove the danger from the equation.

This framework is critical for any safety leader because it shows that relying on weaker controls like procedures or PPE is a recipe for failure. Those methods depend entirely on people doing the right thing, every single time, without fail. In high-pressure environments like construction or manufacturing, that’s a gamble you can’t afford to take.

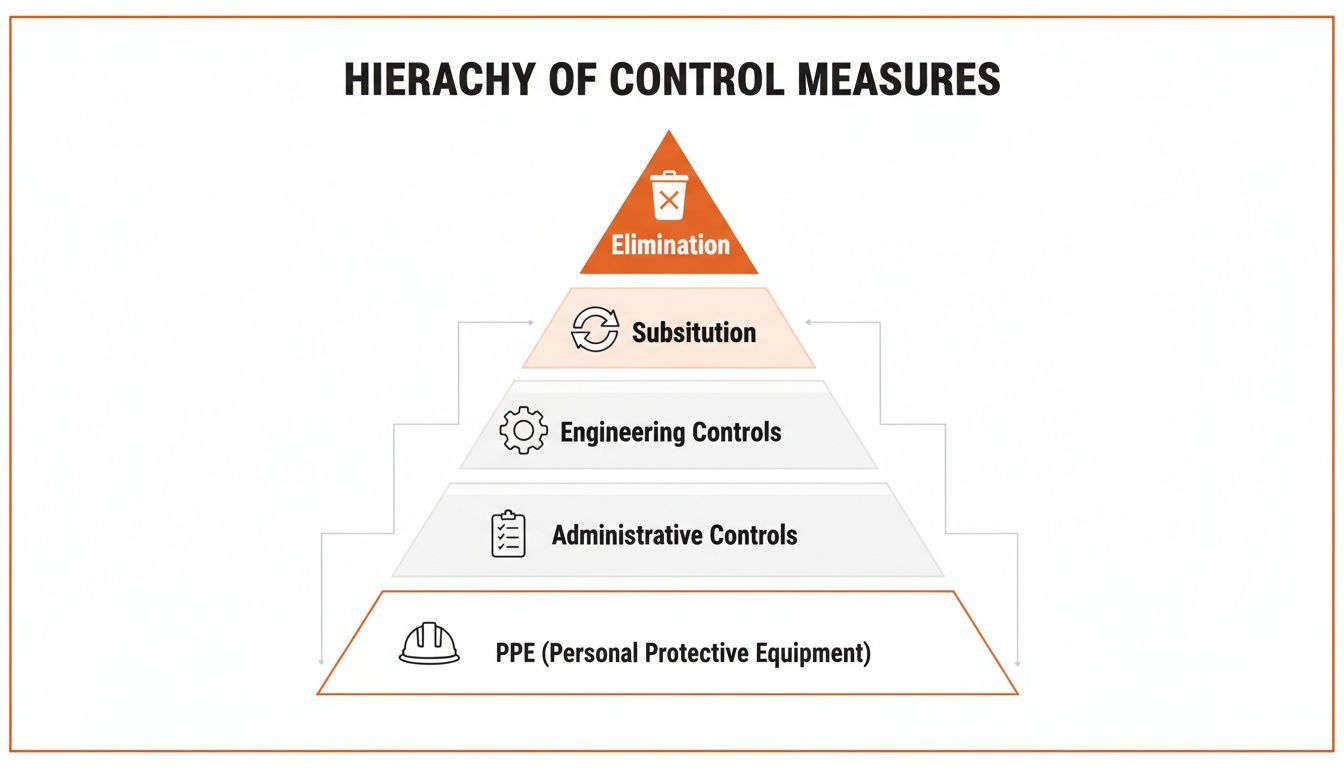

This inverted pyramid shows the 5 levels of control, ranked from most effective at the top to least effective at the bottom.

As you can see, Elimination and Substitution sit at the top. Why? Because they physically remove or reduce the hazard itself, offering the highest level of protection possible.

The 5 Levels of the Hierarchy of Controls

The system organises controls into five distinct categories. The goal is to always start at the top of the pyramid and work your way down. You should only move to a lower, less effective level if the one above isn't reasonably practicable.

Here’s a quick rundown of each level to get us started.

| Level | Description | Effectiveness |

|---|---|---|

| Elimination | Physically remove the hazard entirely. | Most Effective |

| Substitution | Replace the hazard with a safer alternative. | Very Effective |

| Engineering | Isolate people from the hazard with physical barriers. | Moderately Effective |

| Administrative | Change the way people work (e.g., procedures, training). | Less Effective |

| PPE | Protect the worker with personal safety gear. | Least Effective |

It's clear that the further down the pyramid you go, the more you're relying on human action to keep people safe and the less reliable your solution becomes.

A common mistake is jumping straight to the bottom. Handing out hard hats and high-vis vests feels like you're doing something, but it's a band-aid solution that does nothing to address the root cause of the danger.

True safety management starts at the top. In the sections that follow, we'll break down each of these five levels with practical, real-world examples you can use on your site.

Elimination And Substitution: The Most Effective Controls

At the very top of the control measures hierarchy sit elimination and substitution. These strategies tackle hazards right at their source instead of simply shielding people from harm. By prioritising them, you’re taking a proactive approach that offers the highest level of protection.

Making adjustments during the design and planning stage often saves time and money compared with trying to manage risks once they’re already in play. When you identify hazards before work begins, you can engineer them out entirely. Modern safety management systems, like Safety Space, flag these opportunities during initial risk assessments.

How Elimination Works In Practice

Elimination means removing the hazard so it no longer exists in your workplace. This isn’t about protecting people from danger, it’s about making the danger disappear. In terms of risk control, it’s the gold standard.

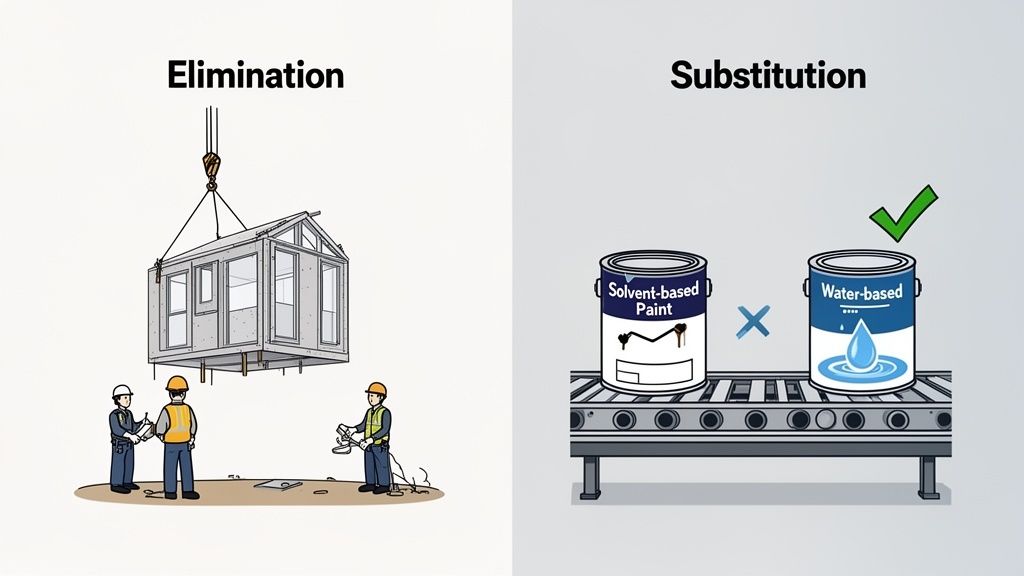

Imagine a roofing job that normally requires workers on a ladder. Instead of fitting harnesses and guardrails, you redesign the process so panels are assembled on the ground and lifted into place. The fall hazard isn’t just reduced, it’s completely gone.

Elimination delivers a 100% reduction in risk because it erases the hazard from the equation. Always consider it first in any risk assessment.

Practical examples of elimination in construction and manufacturing:

- Avoiding Work at Heights: Prefabricate roof sections on the ground, then use a crane for installation.

- Removing Hazardous Materials: Re-engineer a cleaning process so a toxic solvent is no longer required.

- Automating Dangerous Tasks: Deploy a robot to handle repetitive, high-risk manual operations.

When To Use Substitution As A Control

If you can’t eliminate a hazard, the next step is to substitute it with something safer. Substitution involves swapping out the riskier material, process or equipment for a less hazardous alternative.

It won’t remove all risk, but a well-chosen substitute can greatly reduce the chance of harm. The catch? You must check that your replacement doesn’t introduce new dangers. A quieter machine might still vibrate excessively, so a full assessment is vital.

Practical Examples Of Substitution

Organizations that start with substitution often see big safety gains. In one study, Australian construction firms that applied these top-tier controls recorded a 47% reduction in incidents compared with those relying on lower-level measures.

- Safer Materials: Switch from solvent-based paint to water-based or low-VOC formulas.

- Prefabricated Components: Bring in factory-made wall panels to cut on-site cutting and dust exposure.

- Better Equipment: Replace heavy, outdated power tools with lighter, ergonomically designed models.

- Changing a Process: Use a hydraulic press instead of manual hammering to assemble components.

By beginning every risk assessment with elimination and substitution, safety managers build more robust systems. These controls don’t hinge on the right procedure being remembered or gear being worn correctly. They’re inherently more reliable and form the foundation of any solid safety programme.

How to Use Engineering Controls to Isolate Hazards

So, you can’t completely eliminate a hazard, and substituting it isn’t practical. What’s next? This is where you bring in the heavy hitters of the control measures hierarchy: engineering controls.

The idea is simple but powerful: physically separate your people from the danger. Instead of relying on someone to follow a rule or wear the right gear, you change the workplace itself. Engineering controls are physical solutions like barriers, guards, and systems built right into the environment.

Think of them as permanent safety features working in the background. They don’t need constant human attention to be effective, which makes them one of the most reliable ways to manage risk.

Key Types of Engineering Controls in Industry

Engineering controls come in all shapes and sizes, from a simple guard on a saw to a complex ventilation system that covers an entire factory floor. But they all share the same goal: create a physical barrier or remove the hazard at its source before it ever reaches a worker.

This approach is a game-changer in busy, dynamic places like construction sites and manufacturing plants.

You’ll see them everywhere if you know what to look for:

- Machine Guarding: This is the classic example. Installing fixed guards, safety cages, or even light curtains around moving machine parts to make it impossible to make contact.

- Ventilation Systems: Using local exhaust ventilation (LEV) to suck up nasty stuff like silica dust or welding fumes right where they’re created. It’s about capturing the problem before it contaminates the air everyone is breathing.

- Sound Enclosures: Got a noisy piece of equipment? Build a soundproof box or barrier around it. This dramatically cuts down the decibel levels for everyone working nearby.

- Isolation of Processes: If an operation is particularly hazardous, wall it off. Put it in a separate, contained room to drastically limit the number of people who could ever be exposed.

These aren’t just nice-to-haves; they deliver real results. In Australian industrial firms, it’s estimated that properly implemented engineering controls prevent around 14,500 serious injuries every single year. Digging deeper, in southern Australia's manufacturing hubs, machinery incidents account for 18% of all claims. But businesses that invested in guards and ventilation saw these incidents plummet by an incredible 55%.

Assessing and Maintaining Engineering Controls

Putting an engineering control in place is just the first step. For it to keep working, you have to look after it. Over time, guards get damaged, ventilation filters clog up, and safety interlocks can fail. Without a solid maintenance plan, your best line of defence can quickly become useless.

Your assessment and maintenance schedule needs to be locked in:

- Initial Commissioning: The moment it's installed, test it. Confirm it’s working exactly as designed and actually reducing the risk. This could mean doing air quality monitoring for a new ventilation system or taking decibel readings for that new sound enclosure.

- Regular Inspections: Set up a routine of visual checks and functional tests. For instance, machine operators should check their guards at the start of every shift, and critical safety interlocks should be tested weekly. No excuses.

- Preventative Maintenance: Just follow the manufacturer's guide. Clean the filters, lubricate the moving parts, and replace worn-out components before they break.

- Worker Feedback: Your team on the ground uses these controls every single day. They’re often the first to spot when something is off. Listen to them.

An engineering control that isn't properly maintained can create a false sense of security, which is sometimes more dangerous than having no control at all. Regular checks are non-negotiable.

Practical Application in Construction and Manufacturing

In high-risk sectors, engineering controls are vital. Take manufacturing, where a common hazard is exposure to dangerous electrical energy during maintenance. A perfect example of an engineering control here is a Residual Current Device (RCD), which physically cuts the power flow to prevent electric shock. It works automatically, without anyone needing to do a thing.

Now, think about a construction site. Cutting concrete kicks up a huge amount of silica dust, which is a massive health risk. Sure, workers can wear masks (PPE), but a far better solution is an engineering one. Use a saw with a built-in water feed to suppress the dust at the source, or hook it up to an industrial vacuum that sucks the dust away the second it's created.

By prioritising engineering controls, you shift the safety burden from the worker to the work environment. You’re building a more forgiving system, one where a simple human mistake is far less likely to end in a serious injury. That’s how you create a workplace that is fundamentally safer and more productive.

Administrative Controls and PPE: Your Last Line of Defence

When you’ve worked your way down the hierarchy of controls and the higher-level options just aren't feasible, you’re left with the final two tiers: administrative controls and Personal Protective Equipment (PPE). Think of these as your last lines of defence. It’s absolutely critical to understand why they are considered the least reliable.

Unlike the big guns, elimination or engineering controls that physically change the work environment to get rid of a hazard, these lower-level measures hinge entirely on people doing the right thing, every single time. And let's be honest, whenever a control relies on perfect human consistency, the potential for failure goes way up.

What Are Administrative Controls?

At their core, administrative controls are all about changing the way people work around a hazard. They are the rules, procedures, and training programs you put in place to minimise someone’s exposure to risk. They don't actually remove the hazard, but they create a framework for safer work habits.

These controls are often the quickest and cheapest to roll out, which is why, unfortunately, many organizations lean on them as a default. The catch is, they are only as effective as the people following them.

Here are a few classic examples of administrative controls in action:

- Safe Work Procedures (SWPs): These are your documented, step-by-step guides for getting a high-risk task done safely.

- Job Rotation: Limiting how long a worker is exposed to a specific danger, like operating a high-vibration jackhammer or working in a scorching hot environment.

- Safety Training: Equipping your team with the knowledge to spot hazards and stick to the safety protocols you’ve established.

- Warning Signs and Labels: Simple but effective. Using clear signage to alert people to dangers like "Confined Space" or "High Voltage".

The Last Resort: Personal Protective Equipment (PPE)

Sitting at the very bottom of the pyramid is PPE. This covers everything from hard hats and safety glasses to respirators and fall arrest gear. PPE acts as the final barrier between a worker and a hazard, but it’s a fragile one.

Here’s the fundamental weakness of PPE: it does nothing to remove or reduce the actual hazard. A hard hat might protect your head, but it doesn't stop the brick from falling in the first place.

Relying on PPE as your primary control is a major red flag for a weak safety system. It means you’re accepting the hazard’s presence and putting the entire burden of safety squarely on the individual worker's shoulders.

Worse still, PPE only protects the person wearing it, and only if it’s the right type, fitted correctly, properly maintained, and used without fail every single time. One mistake, one forgotten piece of gear, or one damaged item can lead to a catastrophic failure. Make sure you get this right by checking our detailed guide on how to manage your personal protective equipment requirements.

Why These Controls Often Fail

The biggest reason administrative controls and PPE are at the bottom is their total reliance on human action. People get complacent, they make mistakes, they forget procedures, or they take shortcuts, especially when they're under pressure to get a job done.

The data from Safe Work Australia paints a pretty stark picture. Administrative controls and PPE, while being the most common measures in Aussie workplaces, are also the least effective. They successfully mitigate only 28% of hazards, compared to a whopping 72% for higher-tier controls. In the construction industry, a concerning 58% of firms rely mainly on these last-resort measures. This practice is linked to 4,900 fatalities between 2009-2023, where PPE failures were a contributing factor in 22% of those tragic cases.

Making Your Last Line of Defence Stronger

Look, even though you should always be aiming for higher-level controls, sometimes administrative and PPE measures are a necessary part of a layered safety plan. When you have to use them, your goal is to make them as tough and reliable as possible.

Here’s how to do that:

- Develop Clear and Usable Procedures: Write your SWPs in plain English, use pictures or diagrams, and get the workers who actually do the job involved in writing them. A procedure that just sits on a shelf collecting dust is completely useless.

- Conduct Effective, Hands-On Training: Don't just tick a box. Training needs to be practical, engaging, and repeated regularly. People need to practice skills, not just sit through another PowerPoint.

- Implement a Rigorous PPE Program: Your management of PPE has to be top-notch. This means:

- Proper Selection: Choosing the right gear for the specific hazard. No one-size-fits-all approach.

- Fit Testing: Making sure equipment like respirators and harnesses fits each individual correctly. A poor fit is as good as no protection.

- Maintenance Schedule: Creating and enforcing a strict schedule for inspecting, cleaning, and replacing PPE.

- Clear Accountability: Everyone should know who is responsible for issuing, inspecting, and managing the PPE stock.

Ultimately, while administrative controls and PPE have their place, they should only ever supplement stronger controls, not replace them. A safety strategy built only on procedures and gear is a strategy built on hope. And hope is never enough to keep your people safe.

Putting the Hierarchy into Action on Your Job Site

Knowing the theory behind the hierarchy of controls is one thing, but actually applying it on a busy construction site or factory floor? That’s a whole different ball game. The real trick is turning that conceptual pyramid into a practical, repeatable workflow that your team can actually use to make clear, defensible safety decisions.

Your goal should be to create a system that’s not just effective but also easy to audit. When you document your thinking at each step, you create a clear trail showing why a particular control was chosen. It’s the simplest way to prove due diligence and make compliance checks a breeze.

Start with a Thorough Risk Assessment

Every solid safety plan kicks off with a proper risk assessment. It’s simple: you can't control a hazard you haven't identified. This first step means systematically inspecting the work area, the tasks being performed, and the gear being used to pinpoint anything that could cause harm.

Picture a manufacturing floor with a metal stamping process. A good assessment would flag hazards like moving machine parts, deafening noise levels, and razor-sharp metal edges. Each of these needs to be on your list before you can even think about what to do next.

Systematically Work Down the Hierarchy

Once a hazard is identified, you need to work your way down the hierarchy, starting at the top. This is non-negotiable. You have to start with Elimination and document why you can or can't apply it before even looking at the next level. This discipline stops you from making the most common mistake in the book: jumping straight to the easiest fix, like handing out some PPE.

Let’s take a classic construction example: working on a roof.

- Elimination: Can we build the roof trusses on the ground and crane them into place? If so, great, the fall hazard is gone. If not, you need to document why (e.g., site access is too tight for a crane) and move on.

- Substitution: Is there a different roofing material we could use that needs less time working at height? It might not be practical, but you have to ask the question and record the answer.

- Engineering Controls: Can we install guardrails around the entire roof edge? This is a fantastic control because it physically separates people from the hazard.

- Administrative Controls: Now we’re getting into rules and procedures. We could implement a strict ‘no-go zone’ near unprotected edges or require a permit-to-work system for all roofing tasks.

- PPE: Finally, we get to the last line of defence. Mandate full-body harnesses and fall arrest systems for anyone who has to work near the edge.

This structured process ensures you land on the most effective controls that are reasonably practicable. Having a clear workflow like this is a cornerstone of any decent construction safety management plan.

Documenting Your Control Measures

Good documentation isn't just about ticking compliance boxes; it’s about creating a bulletproof record of your risk management process. For every hazard you find, your documentation should spell out:

- The hazard itself (e.g., "unguarded conveyor belt").

- The potential harm (e.g., "risk of entanglement, serious injury").

- The controls you chose, starting from the top of the hierarchy.

- A clear reason why higher-level controls weren't used.

- Who is responsible for putting the control in place and making sure it stays effective.

This record creates a transparent audit trail. The principle of building an effective trucking company safety program is about systematically tackling hazards at every level, and that logic holds true for every industry, from transport to manufacturing.

A well-documented process proves you’ve done more than just spot risks; it shows you have actively and systematically worked to control them using an accepted best-practice framework. This absolutely cuts down on the admin headache during audits and incident investigations.

This system also greatly improves how you manage subcontractors. By requiring them to follow the same hierarchical process, you get clear visibility into their safety planning. It ensures they aren't just defaulting to PPE but are actually thinking critically about finding better, more robust solutions to manage risks on your site.

A Practical Checklist for Applying the Hierarchy of Controls

Putting the hierarchy of controls into practice doesn't have to be some complex, academic exercise. It's really just a systematic way of thinking. The key is to tackle every hazard by starting with the most effective control and only moving down the list when you absolutely have to.

This checklist gives your team a straightforward framework to follow on any job site. Think of these questions as a guide to use during your risk assessments to make sure you're making the smartest safety decisions possible.

Step 1: Identify the Hazard

First things first, you can't control a risk until you know exactly what you're dealing with. Get specific.

- What's the actual task or piece of equipment? (e.g., We're cutting concrete blocks with a 9-inch grinder.)

- What's the source of harm here? (e.g., The big one is respirable crystalline silica dust.)

- Who is getting exposed, and for how long? (e.g., The operator is right in the thick of it, plus anyone working nearby for about four hours per shift.)

Step 2: Start with Elimination

This is your first and most important question. Can we just get rid of the hazard completely?

- Can we redesign the process so this task isn't even necessary? (e.g., Can we just order pre-cut blocks to size?)

- Is there a way to change the work environment to remove the hazard? (e.g., Could we assemble this structure at ground level and then lift it into place, avoiding the awkward cutting?)

If the answer is "yes" to elimination, you're done. You've hit the gold standard of safety for this hazard. If not, you need to document why it isn't feasible and then move on to the next step.

Step 3: Move to Substitution

Alright, if elimination is off the table, can we swap the hazard for something less dangerous?

- Is there a safer material we could use to do the same job? (e.g., Using a different building material that doesn’t contain silica.)

- Can we use a different, less hazardous piece of gear? (e.g., Using block splitters instead of a grinder would dramatically reduce dust.)

- And a crucial follow-up: does this new option introduce any new hazards we haven't thought about?

Step 4: Consider Engineering Controls

When you can't eliminate or substitute, the next best thing is to physically isolate people from the hazard. Think physical barriers and smart equipment.

- Can we install a physical barrier? (e.g., Proper machine guards, or even just temporary fencing to create a buffer zone.)

- Can we use ventilation to capture the dust at the source? (e.g., Attaching an M-class industrial vacuum directly to the grinder shroud.)

- Can we modify the equipment to make it safer? (e.g., Using a grinder that has a built-in water feed to suppress the dust before it goes airborne.)

Step 5: Implement Administrative Controls

When engineering controls aren't quite enough, you need to change how people work around the risk. It’s all about procedures and rules.

- Can we limit how long workers are exposed? (e.g., Setting up job rotation so no one person is on the grinder all day.)

- What specific training is needed for this task? This isn't just about using the tool, but understanding the risks of silica dust.

- Can we set up exclusion zones to keep uninvolved workers out of the area?

Step 6: Provide PPE

This is it: your last line of defence. What do you need to protect your team from the risk that’s left over?

- What specific PPE is required for what’s left of the risk? (e.g., A properly fitted P2 respirator and safety glasses are non-negotiable here.)

- Has every single worker been properly fit-tested and trained on how to use, clean, and maintain their gear? If not, it's just a false sense of security.

Answering Your FAQs on the Hierarchy of Controls

Even with the best plans, putting the hierarchy of controls into practice on a real worksite always throws up a few questions. Here are some straight, no-nonsense answers to the common queries we hear from safety managers out in the field.

How Do I Decide What's "Reasonably Practicable"?

"Reasonably practicable" is a term you'll see a lot in Australian safety legislation. In simple terms, it means you have to do what you’re reasonably able to do to keep people safe. It’s a balancing act, weighing the actual risk against the time, effort, and money needed to fix it.

To figure it out, you need to ask a few key questions:

- How likely is it that someone will get hurt? Is it a one-in-a-million chance or something that could happen any day?

- If it does happen, how bad will it be? Are we talking about a minor cut or a life-altering injury?

- What do we already know about this risk and how to control it? Are there tried-and-true solutions out there?

- Are the right controls available and suitable for our site? Is it a real-world solution we can actually implement?

Cost can only be a factor if it's grossly disproportionate to the risk. You can't just skip a $5,000 engineering fix for a risk that could cost someone their life just to save a bit of cash. Always start at the top of the hierarchy and if you have to move down, you better have a good, documented reason why.

What's the Biggest Mistake Companies Make?

Easy. Starting at the bottom of the pyramid. So many businesses jump straight to writing a new SWMS or handing out more PPE because it feels quick, easy, and cheap.

This is a massive own-goal. It does nothing to fix the actual problem. Instead, it puts all the pressure on your team to do the right thing, 100% of the time, which is just not realistic. People make mistakes. Relying too heavily on PPE is a dead giveaway that your safety approach is reactive, not proactive.

Can I Use More Than One Control for a Single Hazard?

Absolutely. In fact, for any serious risk, you probably should. Think of it as layers of defence. A single control rarely eliminates all risk, so combining them is often the smartest move.

Take a noisy machine on a factory floor, for example. A layered approach might look like this:

- Engineering: First, you build a sound-dampening enclosure around the machine itself.

- Administrative: Then, you create a roster that rotates workers out of that area to limit their daily exposure.

- PPE: Finally, you provide everyone with correctly rated hearing protection as the last line of defence.

This combination gives you multiple chances to prevent harm. But the golden rule never changes: start with the highest-level control you can, and then add others to manage any leftover risk.

Getting the hierarchy of controls right isn't just about ticking boxes; it's about a systematic commitment to finding the most effective solutions first. Safety Space provides the digital toolkit to embed this process into your daily operations. You can conduct risk assessments, document your control decisions, and track how well they're working across all your sites, all in one place. Ready to move beyond messy spreadsheets and put the hierarchy into action? Book a free demo of Safety Space and see how it works.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you implement the strategies discussed in this article.

Explore Safety Space FeaturesRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.